Media

Media Contact

David Plaettner

Head of Corporate Communications

Please understand that the Vibracoustic Media Contact responds only to media inquiries. For all other inquiries please refer to the Contact Us section.

24.04.2024

Vibracoustic engineers and supplies two-chamber air spring system for XPENG G9 all-electric SUV

Vibracoustic, a leading global automotive noise, vibration, and harshness (NVH) expert, has worked with a leading intelligent EV maker, XPENG, to design, develop, and manufacture switchable two-chamber air springs for the new XPENG G9 battery electric vehicle (BEV). The solution provides two distinct levels of stiffness, allowing the vehicle to adapt to different loads and road conditions.

19.03.2024

Vibracoustic’s breakthrough air suspension delivers optimal NVH and dynamics for Audi e-tron GT

Vibracoustic redefines comfort and driving dynamics with advanced three-chamber air springs built in the Audi e-tron GT. The air springs use a complex design with build in safety features and silent valve switching for the air chambers, all while securing comfort and driving dynamics.

19.12.2023

Vibracoustic launches NVH technologies for electrified commercial vehicles

Vibracoustic, a leading global automotive noise, vibration, and harshness (NVH) expert, is developing new NVH technologies to equip commercial vehicles with low- and zero-emissions powertrains. Vibracoustic has leveraged its experience and expertise to anticipate the industry’s evolution and created NVH-optimized mounting systems for battery packs, electric motors and fuel cells.

15.11.2023

Marina Cacciutti new Chief Financial Officer (CFO) at Vibracoustic SE

Marina Cacciutti has been appointed to the Management Board of Vibracoustic SE as Chief Financial Officer as of January 1, 2024.

19.07.2023

Vibracoustic expands production for automotive NVH solutions in China

Vibracoustic, a leading global supplier of automotive NVH solutions, announces the official opening of its plant in Chongqing, China. The opening ceremony took place on July 18th, 2023, with attendance from high-level governmental representatives from Chongqing as well as Management Board members from Vibracoustic.

24.05.2023

All-new electric AC compressor encapsulation improves NVH-performance

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, has developed an encapsulation and mounting solution for the electric refrigerant compressors (eCompressors) found in electrified vehicles. The Encapsulated eCompressor Bracket provides substantial NVH improvements over conventional mounts while also improving compressor protection and efficiency.

10.05.2023

Vibracoustic Green Rubber Project: Sustainable rubber production and recycling

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, is implementing new processes to sustainably source, manufacture, and recycle the rubber used in its products. The ‘Green Rubber Project’ is a comprehensive program to find, validate and utilize sustainable materials, processes, and technologies throughout Vibracoustic’s global production network to contribute to a circular economy.

04.05.2023

Vibracoustic introduces an evolution of its Centronics cabin-leveling air springs with increased damping performance and robustness for commercial vehicles

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, has developed its Centronics cabin air springs to offer increased damping and improve robustness. Next to the increased robustness of the new evolution, the Centronics offer substantial advantages for packaging, parts consolidation, and ease of assembly for commercial vehicle OEMs, as well as increasing performance and lowering lifetime operating costs.

19.04.2023

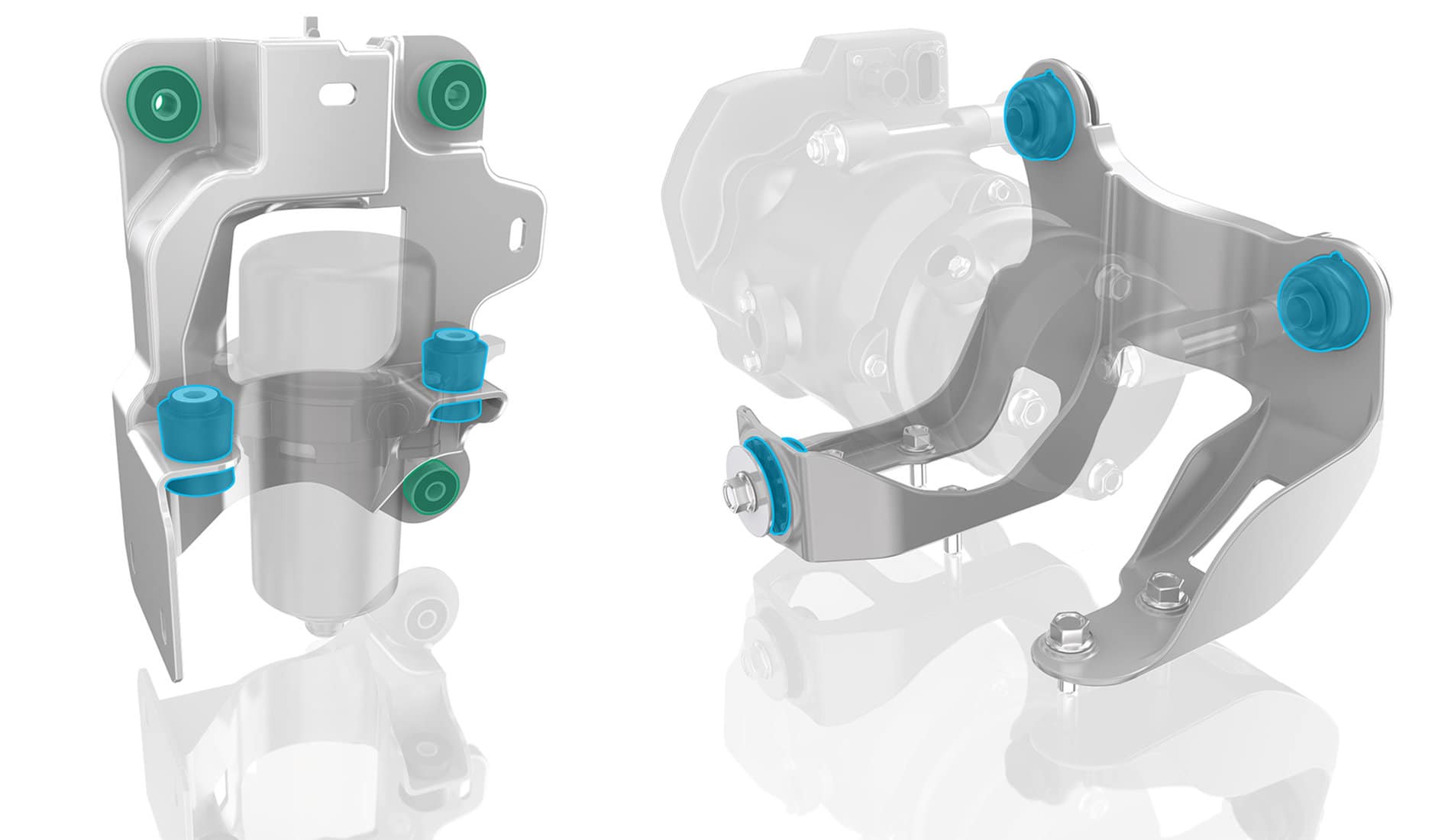

Vibracoustic develops innovative air supply unit bracket with enhanced NVH features

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, has developed a new tunable bracket for air suspension air supply units (ASUs) that improves NVH performance with radial and axial damping, provides reduced weight and complexity and reduces the resonance caused by the compressor excitations.

21.02.2023

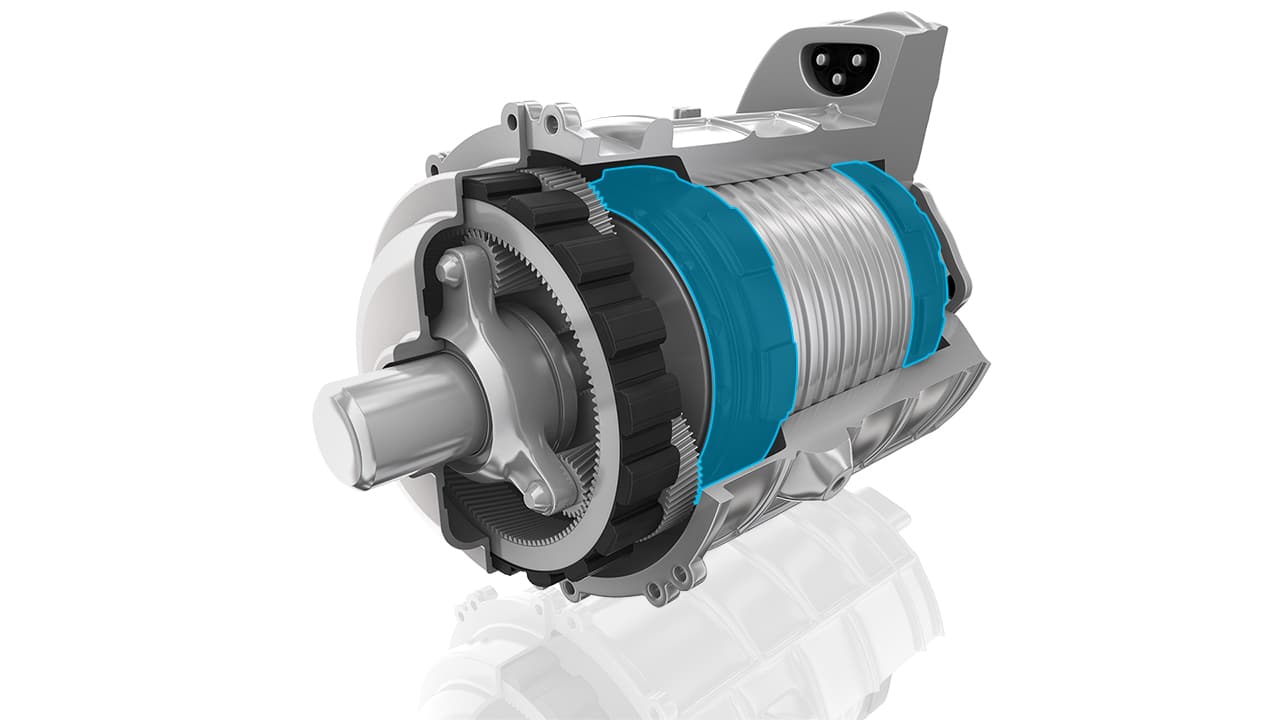

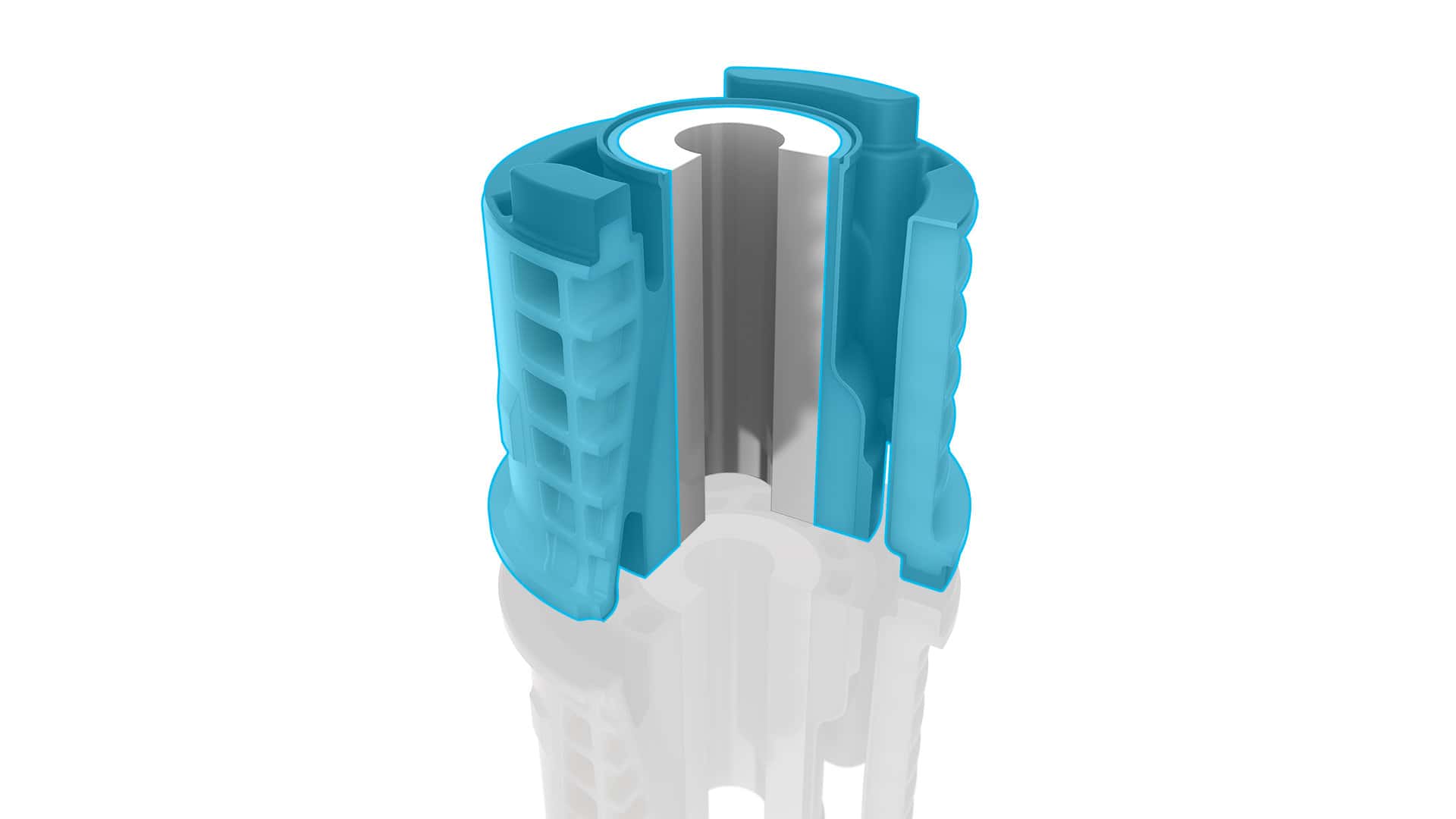

Innovative Stator Isolator reduces torque ripple of e-motors

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, has engineered a unique solution for the torque ripple caused by the fluctuating magnetic fields of e-motors in battery electric vehicles (BEVs). The multifunctional Stator Isolator prevents the transmission of axial, radial and torsional vibrations from the stator into its housing.

08.02.2023

Vibracoustic optimizes chassis bushings for battery electric vehicles

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, brings benefits for battery electric vehicle (BEV) dynamics, durability, noise management and ride quality with its optimized chassis bushings. These are tuned to handle the increased vehicle weight and higher preloads while also ensuring great NVH performance.

14.12.2022

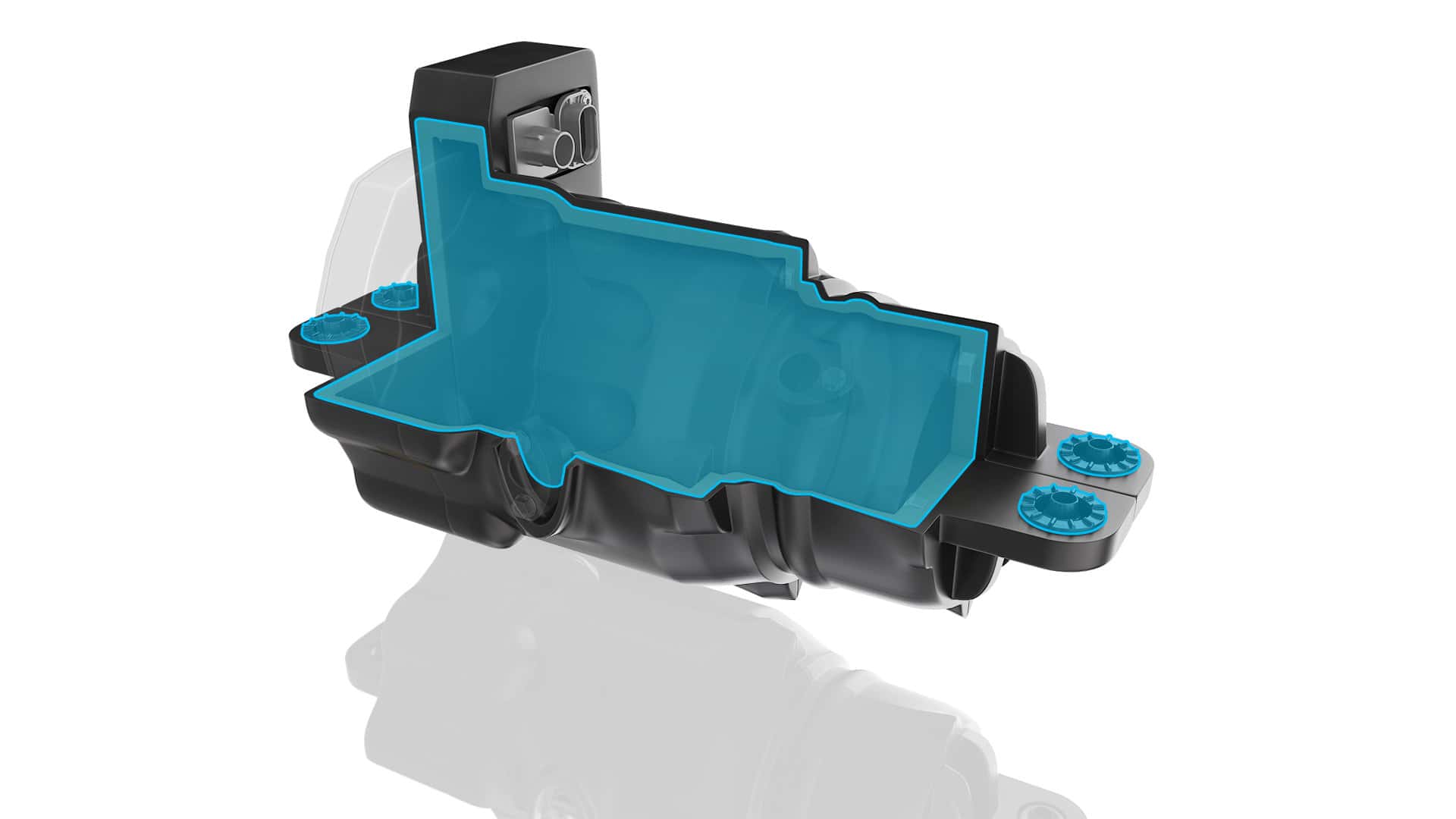

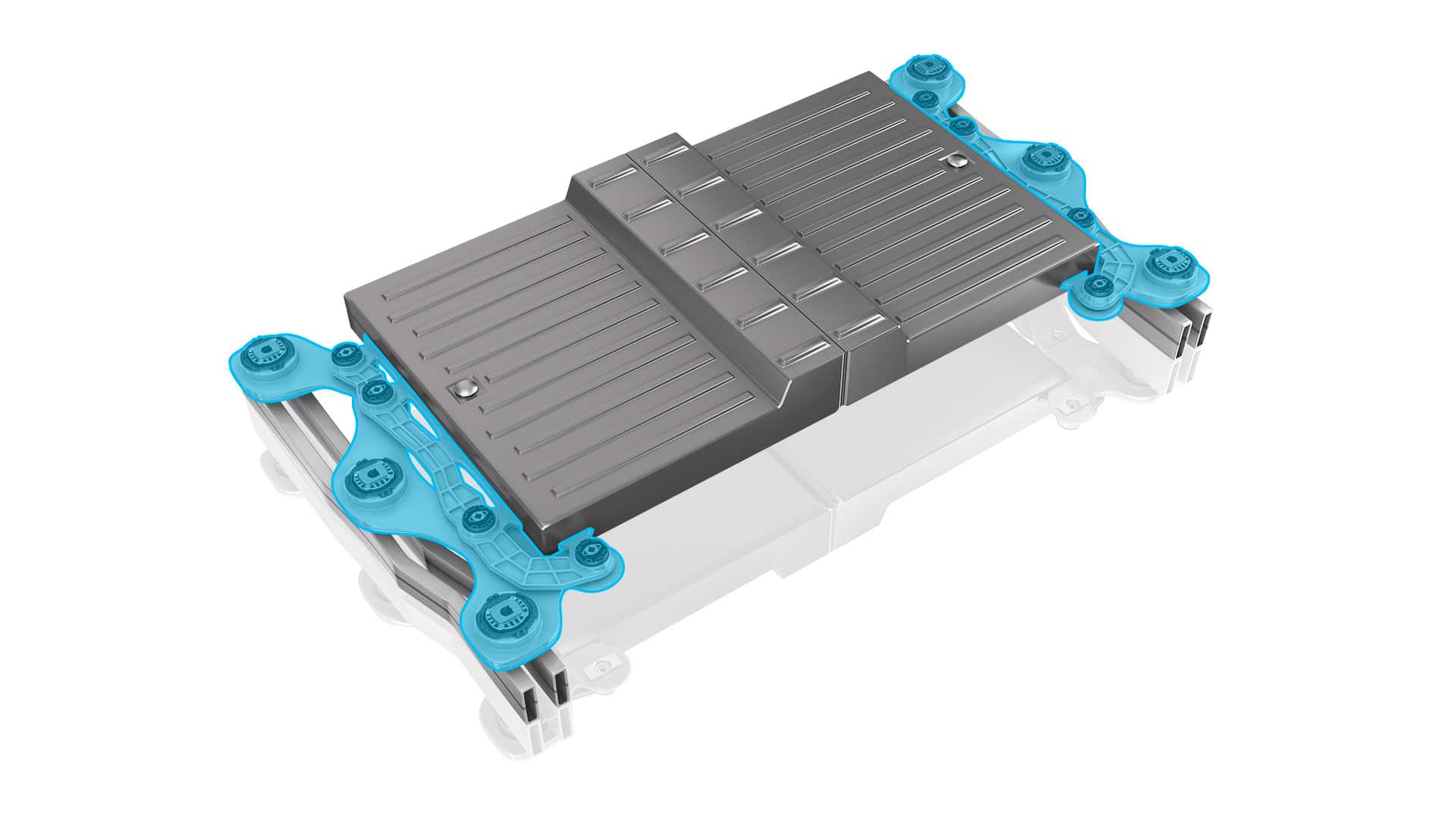

Vibracoustic develops battery pack isolation system for large body-on-frame EVs

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, has developed a battery pack isolation system for body-on-frame vehicles like pick-ups, off-road vehicles, large SUVs and light commercial vehicles. The solution addresses some of the prevailing challenges of heavy battery packs in these vehicle classes.

29.11.2022

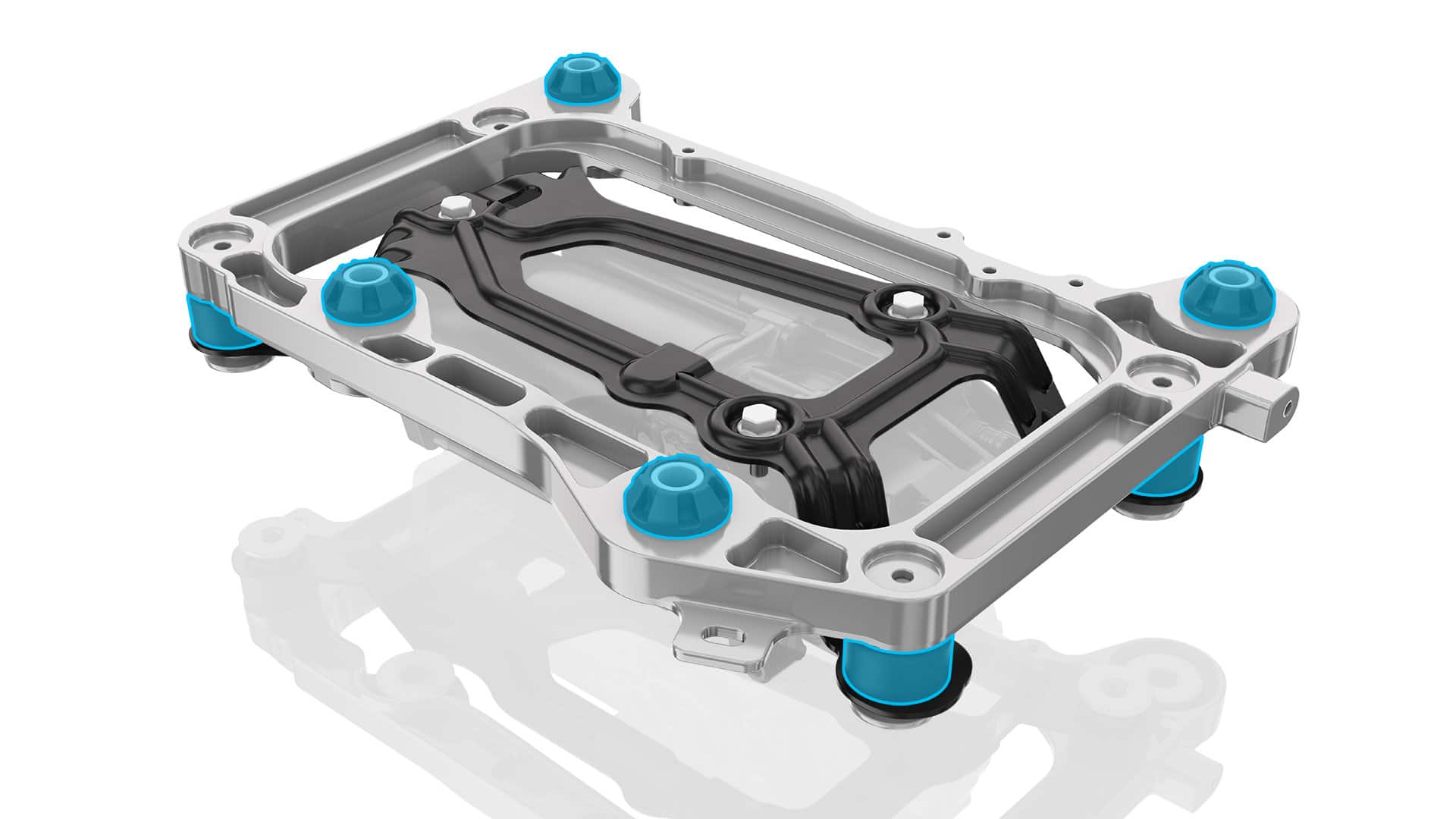

Vibracoustic introduces modular, lightweight mounting solutions for electric motors

Vibracoustic, a leading global automotive NVH (noise, vibration, harshness) expert, presents innovative solutions for electric motors of battery electric vehicles (BEV). The compact polymer beam structure and the integrated thermoplastic elastomer bushings allow full integration, weight reduction and simplification of assembly while also meeting requirements for stiffness and isolation performance. The solutions are offered with different levels of integration, ranging from bushings to a more sophisticated beam mount.

02.08.2022

Vibracoustic hydro leveling technology provides innovative, low-cost active suspension system

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, has developed a cost-effective ride height and suspension leveling system that allows car manufactures to experience height leveling benefits of an air suspension with significantly less complexity and costs.

20.04.2022

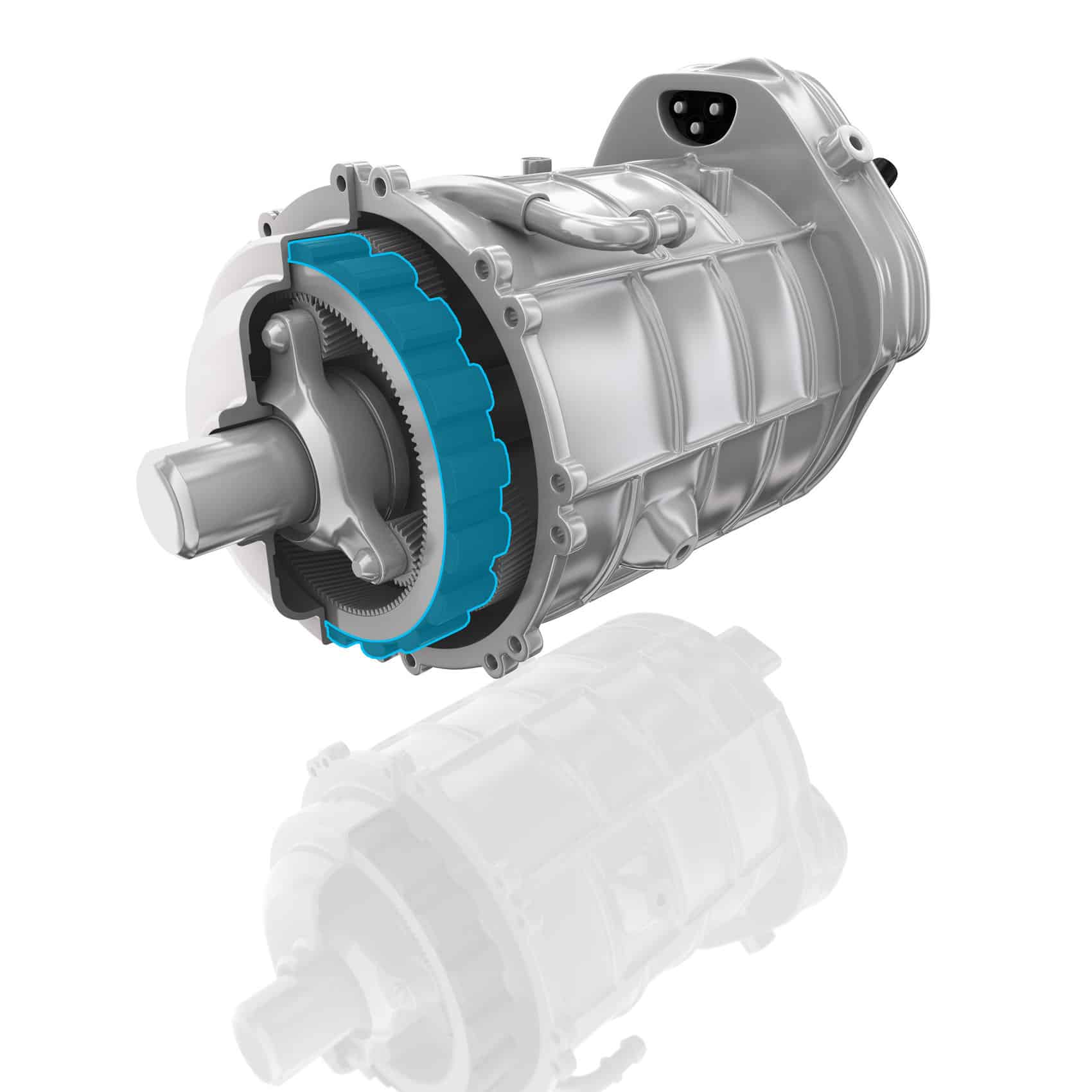

Vibracoustic addresses electric drive unit NVH issues with new elastic ring gear

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, has developed an elastic ring gear to help mitigate electric drive unit (EDU) excitations in electric vehicles (EVs) planetary gearboxes. With vehicle manufacturers confronting new NVH challenges in their EV programs, Vibracoustic is already developing a range of industry-leading solutions.

17.03.2022

Vibracoustic seat dampers enable lightweight and NVH-optimized automotive seat constructions

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, is enabling vehicle lightweighting while also enhancing the passenger experience by reducing seat vibrations. When integrated from the design phase, seat damper can improve NVH performance and lower overall seat construction weight.

23.02.2022

Vibracoustic develops decoupling solutions for electric vehicles

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, is developing a range of decoupling solutions for auxiliary components in electric vehicles (EVs). Automotive manufacturers are facing a range of new NVH challenges as auxiliary systems – like coolers, pumps and compressors – are not belt-driven in e-mobility applications.

20.05.2021

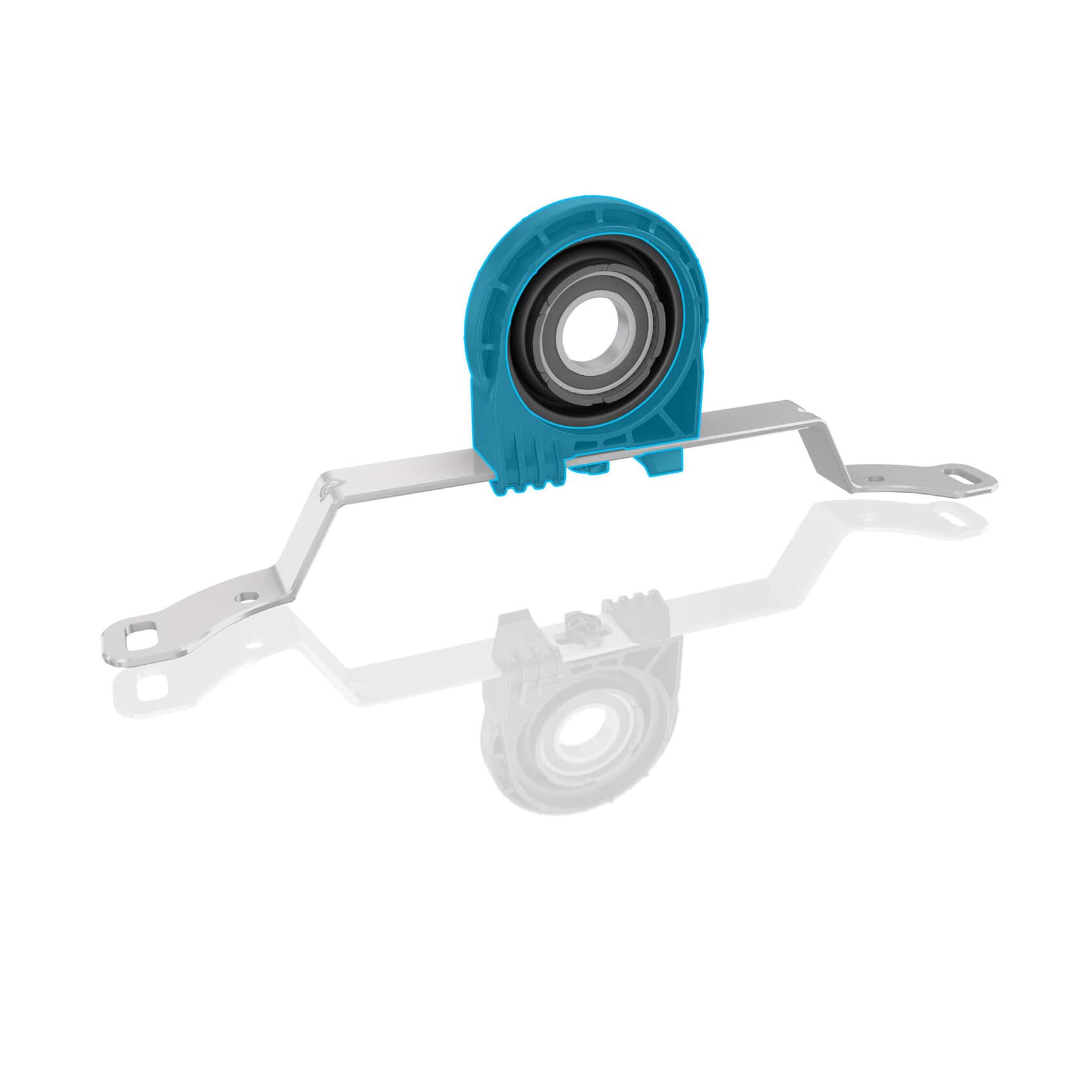

Vibracoustic reduces complexity and weight with new modular center bearing support

Vibracoustic, a global expert in automotive NVH (noise, vibration and harshness) solutions, has launched a new highly-modular, lightweight center bearing support for prop shaft applications that significantly simplifies assembly and packaging while also improving damping and isolation. Using high-performance plastic housing and rubber isolation, the new center bearing support offers an optimized and highly cost-effective solution for modern passenger vehicles.

29.03.2021

Vibracoustic Integrated Top Mount Module Cuts Weight, Cost and Development Time

Vibracoustic, a global leader in automotive NVH (noise, vibration and harshness) solutions, has launched an integrated Top Mount Module for light vehicles. It combines five separate parts – the plastic top mount and integrated bearing, spring seat, dust boot and jounce bumper – in one module. Therewith, the Top Mount Module provides light vehicle manufacturers with space, weight and cost savings while consolidating the full strut function within a single solution.

02.03.2021

Vibracoustic equipped all-electric Hongqi E-HS9 luxury-class SUV with air springs and hydro bushings

Vibracoustic delivers front and rear axle air springs as well as hydro bushings for the new Hongqi E-HS9 to provide excellent driving comfort. The all-electric luxury-class SUV is available on the Chinese market since late 2020 and is the top-of-the-line luxury SUV from Hongqi, the luxury brand of the Chinese car manufacturer FAW.