NVH Solutions | Systems

NVH System Engineering

We are working closely together with vehicle manufacturers, often already during the concept phase of a vehicle, to define product specifications and requirements. Our unique experience and know-how as well as the test and tuning equipment from vehicle to subsystem to component level form the basis of our comprehensive understanding of the full vehicle system. It enables us to be a reliable go-to partner in all phases of the OEM’s vehicle development.

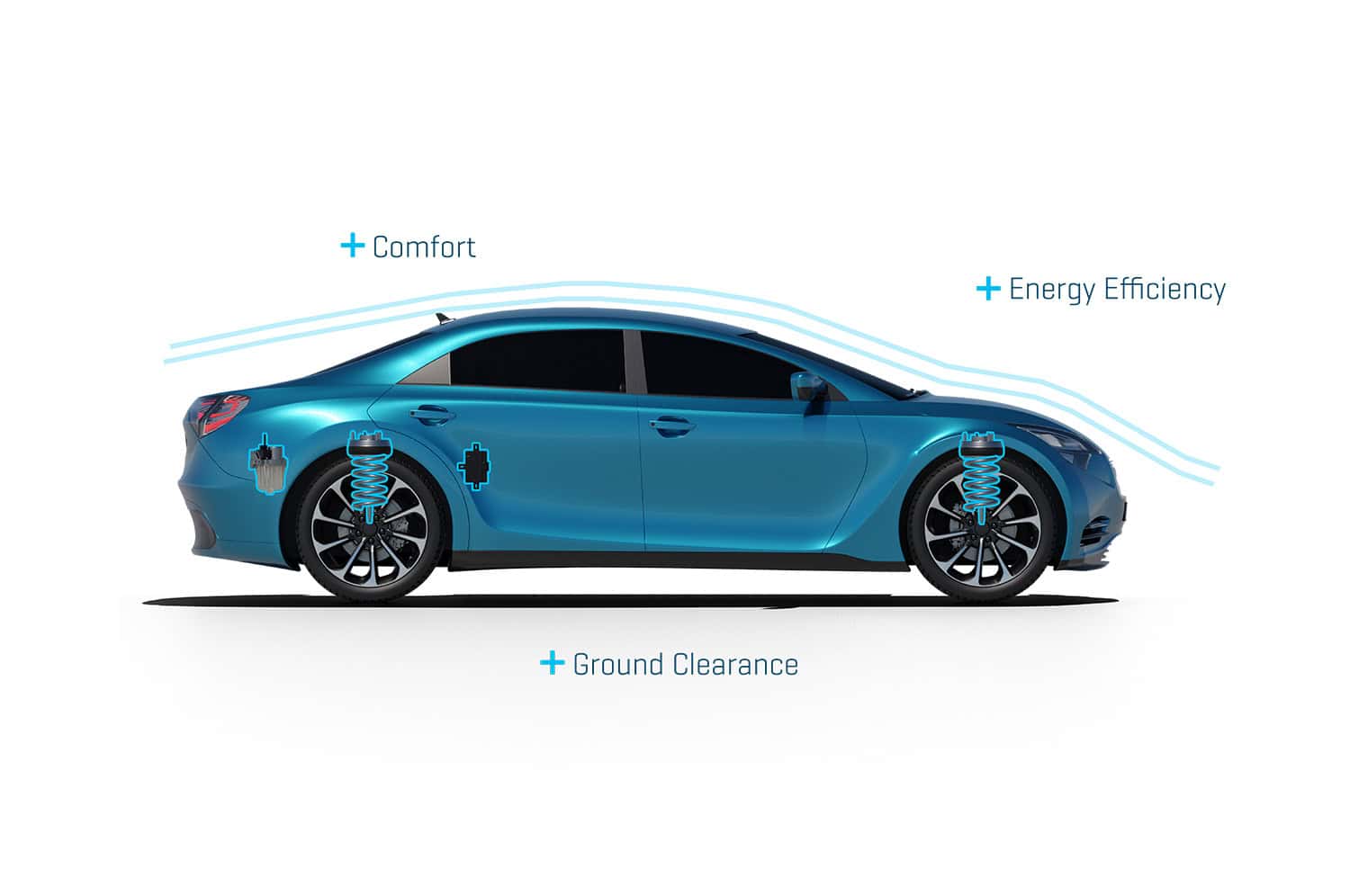

Smart Leveling System

While air suspension is a popular feature among larger EVs and luxury vehicles, models in smaller segments – including compact EVs – often miss the benefits of ride height adjustment and suspension leveling. Vibracoustic’s engineers have developed new cost-effective and easy-to-implement system offers this functionality for both front and rear axle applications. The Smart Leveling System can be used to integrate a range of features into volume vehicles, including improved comfort and customizability, EV battery cooling, energy efficiency and safer trunk loading and unloading. It can also be used to adjust ground clearance, optimizing for speed bumps and driveways, as well as for more aerodynamically efficient high-speed motorway driving.

Axle System Benchmarking & Optimization

Noise, Vibration and Harshness (NVH) optimizations are often required late in the development process. However, more and more OEMs consider addressing these issues much earlier to avoid late, difficult and costly changes. We support these efforts with our axle test bench, which allows to test, benchmark and fine-tune complete axle systems in an early development phase as well as to troubleshoot in any stage of the vehicle lifecycle. Due to our NVH expertise we know how our products behave and react in an axle subsystem as well as in the full vehicle. With over 80 axles benchmarked, we have a unique expertise and are able to derive NVH market trends from these findings.

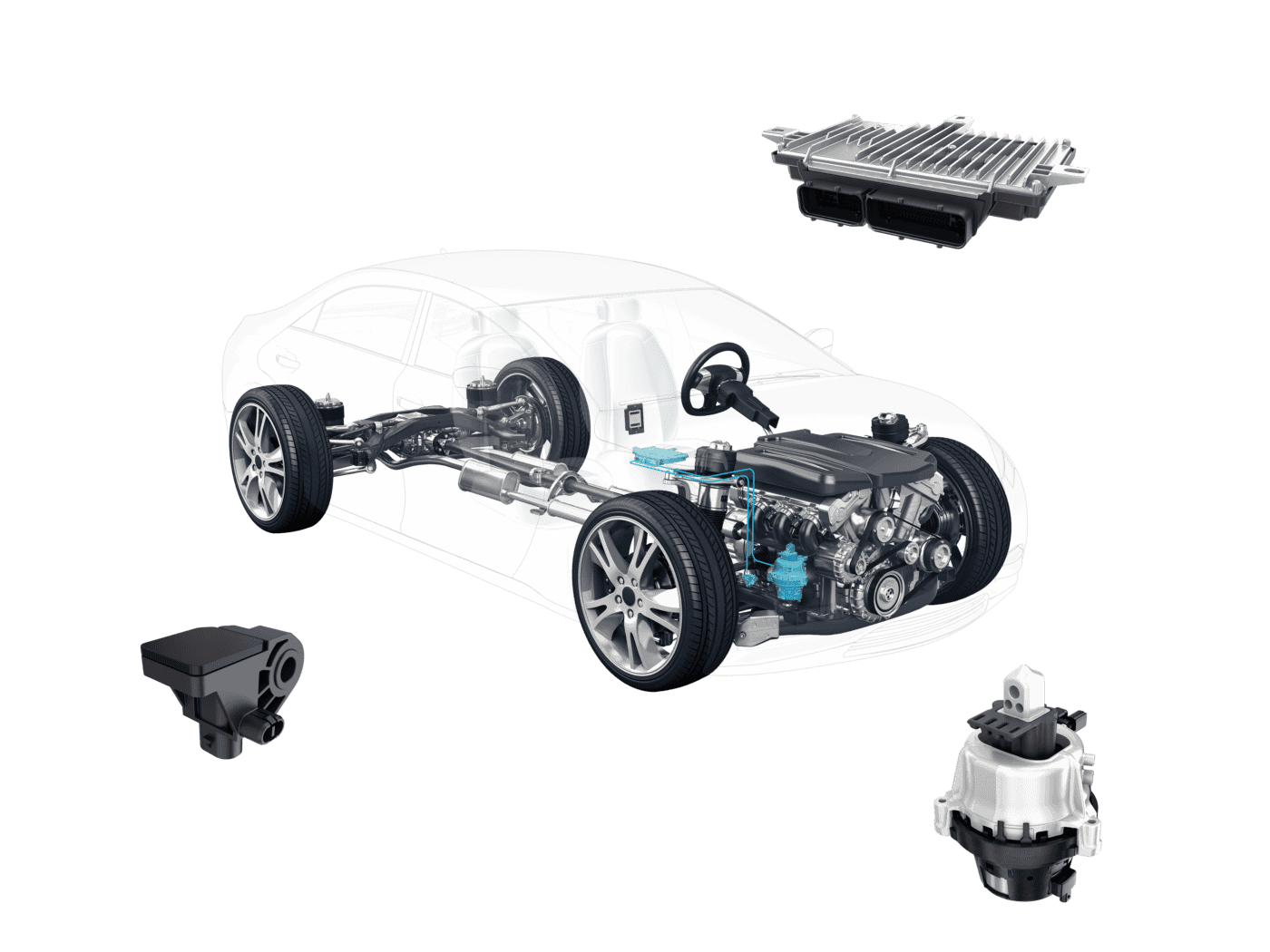

Motor Mount Systems

Engine and motor mounts carry the static and dynamic loads and isolate vibrations from low to high frequencies. To achieve the best NVH performance, the mounts and torque rods need to be precisely tuned and adapted to the specific needs of the manufacturer. With Vibracoustics proprietary motor mount system simulation, we can configure, simulate, benchmark and fine-tune the interaction of the different system components, with each other and with the surrounding vehicle structures, without changing the DNA of the specific vehicle. Furthermore, we can verify the results on our own vehicle and component test rigs.

Active motor mount systems take it one step further and use specially generated counter-vibrations to neutralize the incoming vibrations. Vibracoustic supports light vehicle manufacturers in developing, producing and fine-tuning these active motor mount systems. This includes the development and programming of the base and application software as well as providing the auxiliary hardware like sensors and actuators.