Efficiency

Emission, Weight and Space Saving Solutions

Reducing fuel consumption, increasing the range of an electric vehicle or saving weight and space during the development of a light or commercial vehicle: the requirements to improve efficiency are omnipresent in the automotive industry. We develop NVH solutions which address these efficiency aspects and support our customers in achieving their targets without compromising on comfort and driving dynamics.

Emission Efficiency

The efficient integration of auxiliaries in the belt drive of internal combustion engines is a powerful method to reduce CO2 and consumption levels of up to one percent. A low belt tension can lead to significant efficiency improvements as friction losses are decreased within the belt drive. However, this involves the risk of belt sagging, which needs to be prevented at all costs. To address this challenge, we have developed an overrunning damper isolator pulley which prevents the sagging and flapping of the belt, thus ensuring consistent belt tension in every driving situation.

Variants of the system can be used for gasoline and diesel engines as well as in hybrid drive systems. This can further improve the efficiency of electrified vehicles.

Dr. Joerg Boecking, CTO

Weight Efficiency

Whereas solutions like the overrunning damper isolator pulley have a direct impact on the engine run and its efficiency, weight savings have an indirect but nevertheless important impact on the overall vehicle efficiency.

New rigid and strong thermoplastics enable us to realize innovative lightweight NVH solutions without compromising on performance and durability. Whereas in the past plastic applications were mainly used for housings, which are not exposed to high load and stress, lightweight solutions for all kinds of high load and high stress applications like motor mounts, top mounts or air springs are possible. In these applications, weight savings of up to 50% can be achieved in comparison to conventional steel variants.

We develop thermoplastic products to realize weight savings at scale. Our unique NVH and material expertise together with our understanding of the full vehicle system makes us a strong engineering partner for our customers.

Dr. Joerg Boecking, CTO

Space Efficiency

Customer demands for additional comfort, safety and entertainment equipment are constantly increasing. New components for electrified or electric drive trains need additional space in modern cars. This trend leads to increased space restrictions in the development and construction of modern cars.

Compromising on driving comfort and NVH performance is never an option for us. We always seek to find smart and innovative solutions to fulfill all customer requirements within the given space restrictions.

Dr. Joerg Boecking, CTO

Decoupling Solution for the Drive Train

Our cord-reinforced elastomer coupling NRG-Disc i.e. is smaller and lighter as comparable hardy-disc couplings while providing higher performance in minimizing torsional vibrations and even providing higher durability over its lifetime.

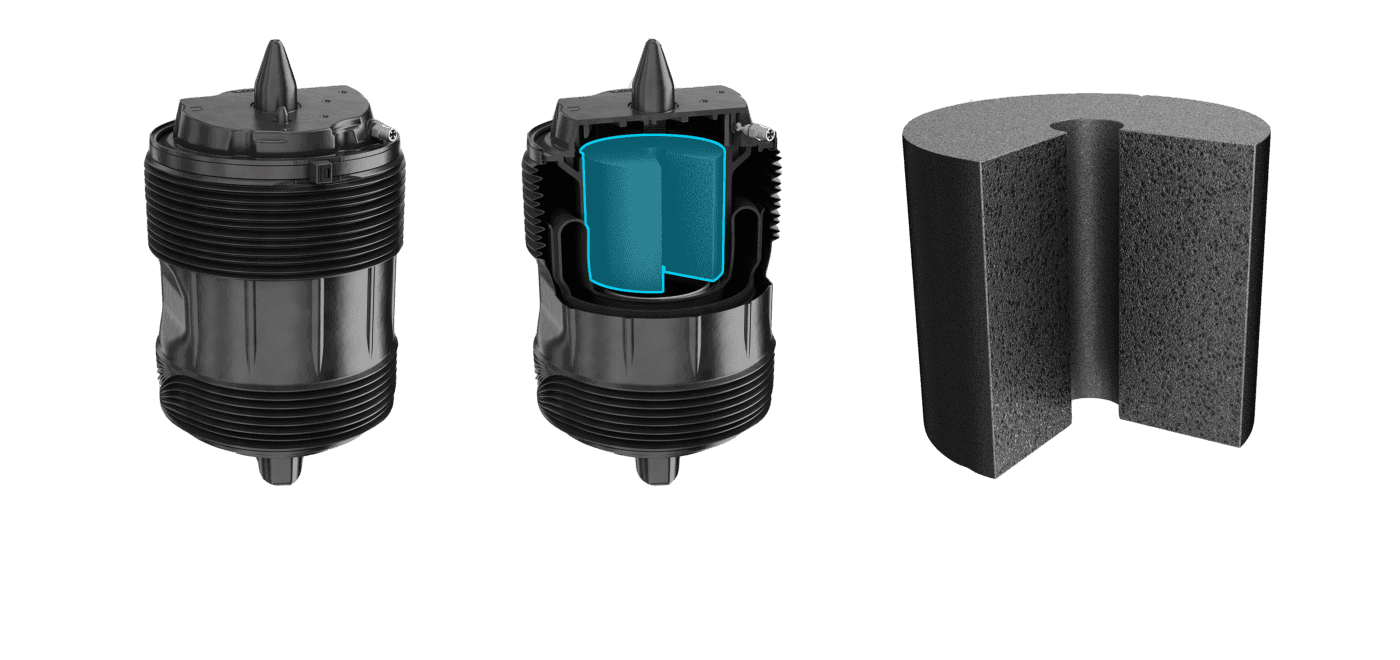

Air spring suspensions offer many benefits in terms of increased comfort and additional functionalities. However, light vehicle manufacturers need to deal with increasingly complex conditions in relation to the available space. Vibracoustic offers a new technology, which provides the same performance with less building space by using a rigid but highly porous activated carbon block, which is integrated within the air volume in the air spring chamber. The numerous, fine-pored chambers in the block increase the effective air volume in the air spring. The additional volume can be more than 20 percent, depending on the pressure in the air spring but without any additional space needed.

Activated Carbon for Application in Air Springs

A higher air volume means a lower spring rate so that the spring can be given a softer, more comfortable design. The addition of activated carbon in an air spring now enables the designers to realize a higher level of comfort using the same building space as before. That is especially helpful for high-class premium vehicles where the comfort demands are constantly rising. The second option is to reduce the building space of the air spring while still achieving the same performance characteristics. The use of activated carbon enables the developers of air springs to create completely new types of designs. Overall, depending on the design, the use of activated carbon has benefits in relation to weight, handling, packaging, and costs.