E-Mobility

NVH Solutions for E-Mobility

Electric mobility is here to stay, there seems to be no doubt about it. But the electrification of the drive train, no matter if fully or partly electric, also affects the comfort and ride experience of the passengers. We are developing new technologies to ensure comfortable, relaxed and safe travel in light and commercial electric vehicles.

Electric vehicles create new challenges in the development of NVH-solutions, as comfort demands and expectations will increase further. We support OEMs in identifying and solving these new challenges to secure a comfortable and safe ride, no matter what powers the vehicle.

Frank Mueller, CEO of Vibracoustic SE

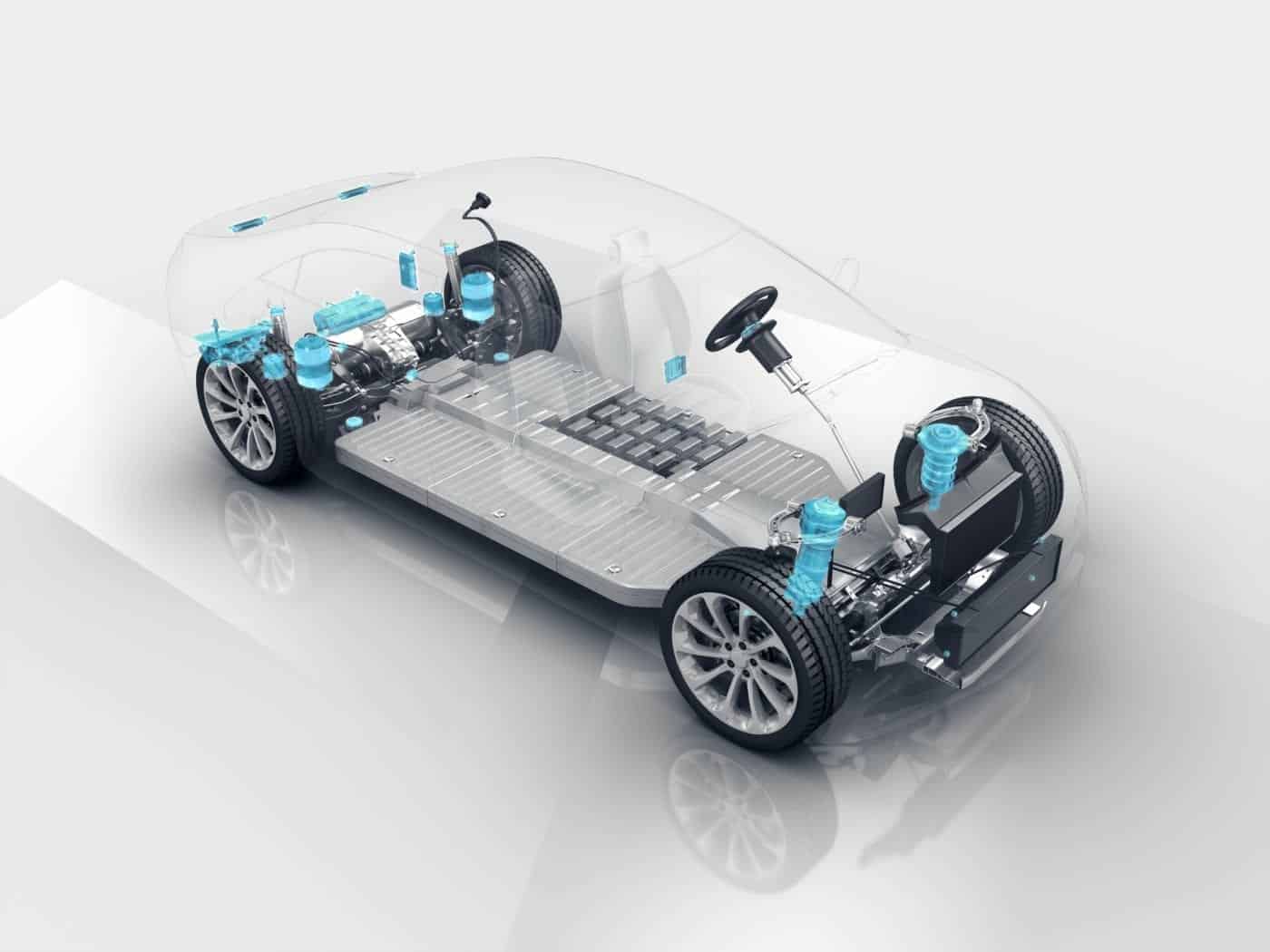

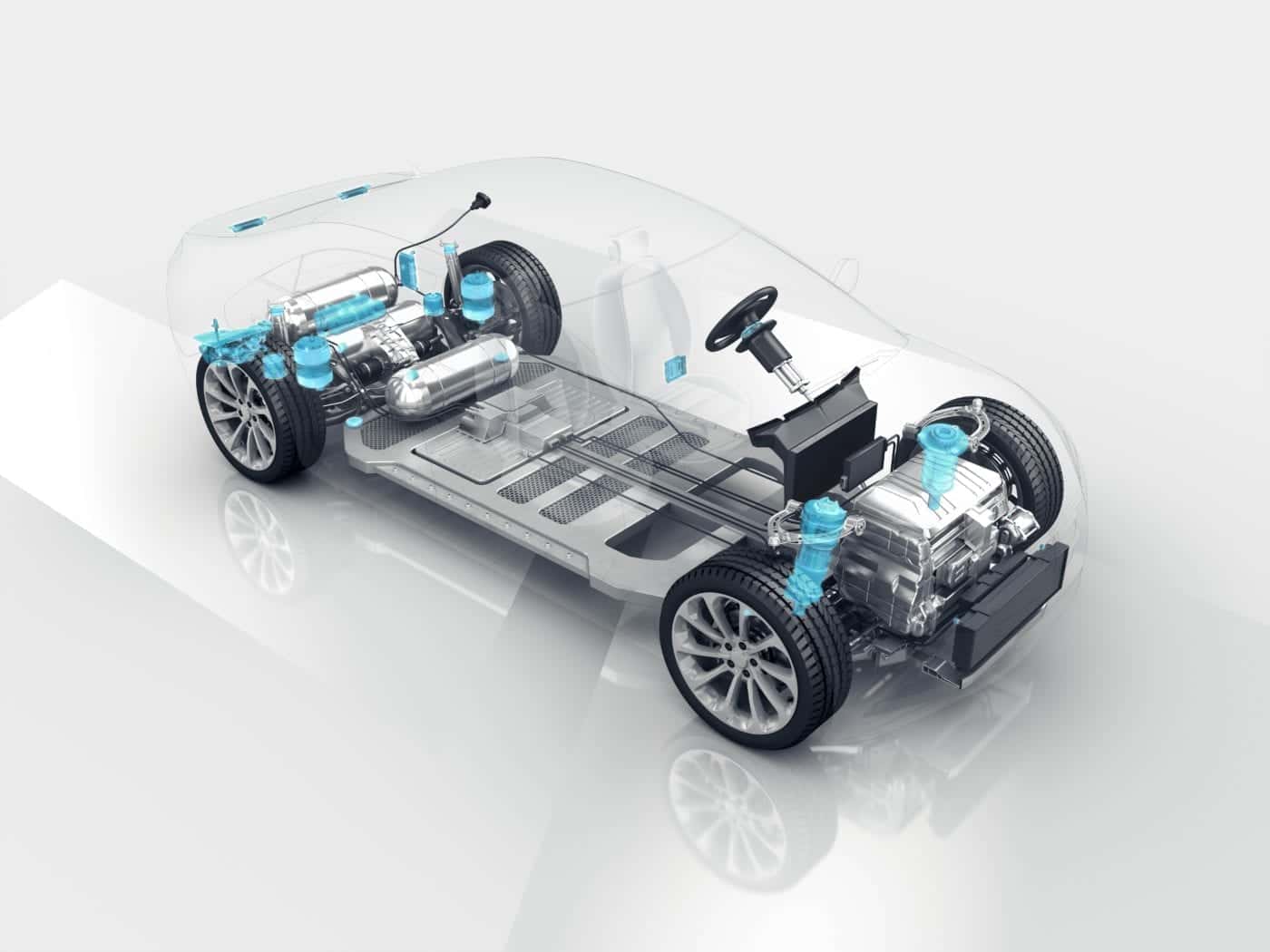

Electric Drive Trains

No more shaking when starting up the vehicle, no revving of the engine or monotonous humming during a long freeway drive. The noise and vibrations that drivers currently regard as perfectly normal are suddenly a thing of the past in battery electric vehicles (BEV) or fuel cell electric vehicles (FCEV).

Previously unheard noises and vibrations become more prominent. At the same time, an electric motor creates vibrations in a completely different frequency range that is more unpleasant for passengers. Whereas a combustion engine produces vibrations mainly between 20 and 400 Hz, an electric engine can produce vibrations of over 10,000 Hz.

Our portfolio of innovative NVH solutions includes, for example, specially developed motor mounts and dampers. These are tuned to address and dampen the high frequency excitations of the electric motor in BEVs and FCEVs in order to minimize the impact on passengers.

On the chassis side, highly robust chassis mounts address the additional weight and resulting higher loads on the chassis of electric vehicles. Air springs not only increase driving comfort and driving dynamics, but they also allow the lowering of the car at high speeds to improve the aerodynamics and thus increase range. Furthermore, this technology can optimize the airflow under the car for better passive battery cooling. When parking, the air springs can also automatically raise the car to allow enough space between the potentially dry surface and the battery packs for safety reasons.

Battery Electric Vehicle

Fuel Cell Electric Vehicle

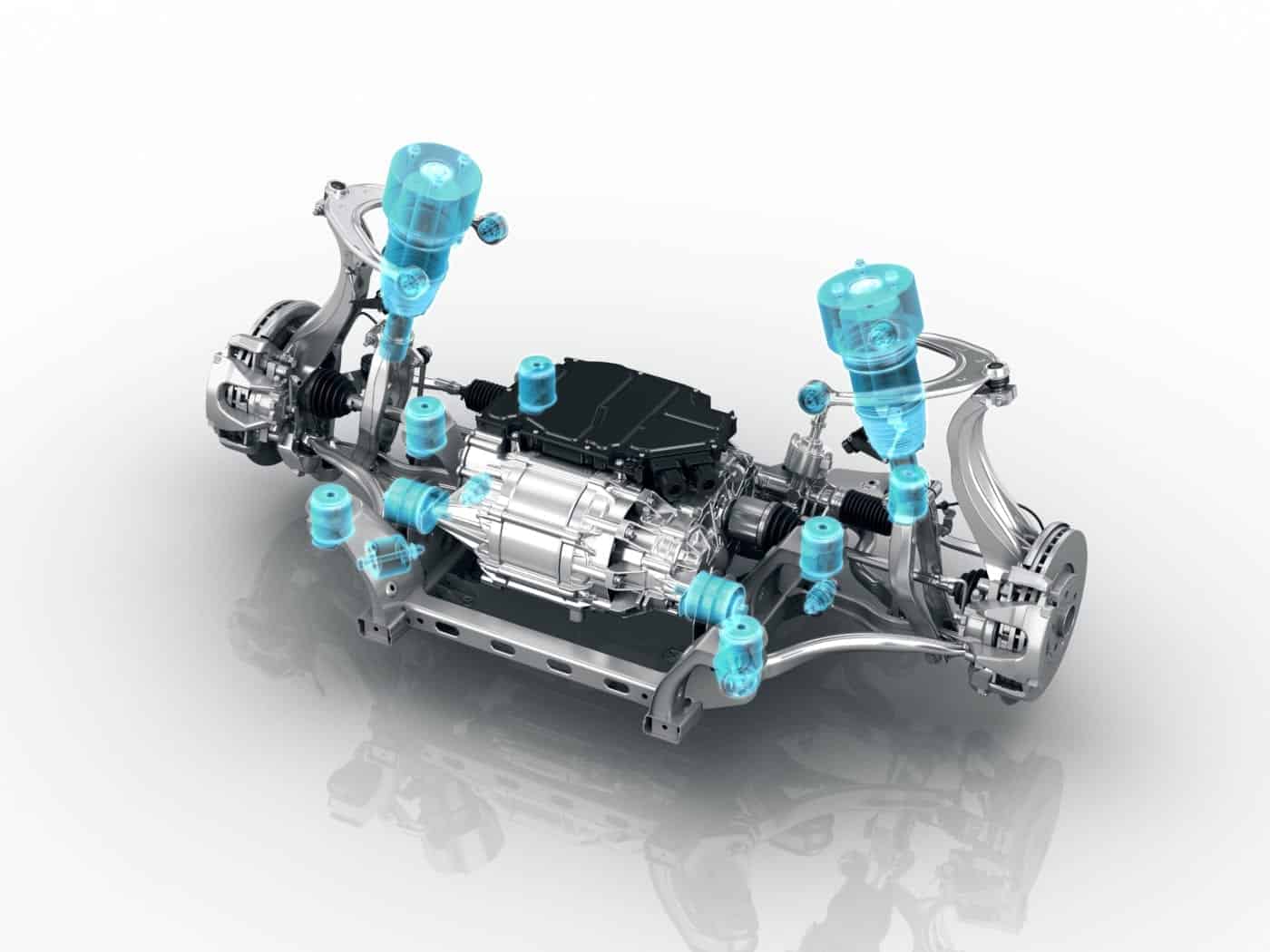

Partnership of Vibracoustic and Benteler: Development of E-Chassis Solutions

To address the needs of light vehicle manufacturers to buy whole subsystems from one source, Vibracoustic and Benteler Automotive have signed a development agreement for the NVH development of the Benteler E-Chassis. Benteler Automotive provides with the E-Chassis a pre-validated front and rear axle system. It includes an electric drive unit (EDU) and is already tuned in terms of NVH criteria, ride, and handling.

Thus, we are able to provide customers with modular and tailor-made e-mobility solutions. Comfort is crucial to the overall driving experience and therefore the partnership between Vibracoustic and Benteler is a perfect fit. With our combined competencies, we can offer customers a pre-validated front and rear axle system which is already tuned for great driving comfort and handling.

Frank Mueller, CEO of Vibracoustic SE

This pre-validated system solution offers several advantages to emerging as well as established OEMs in developing and manufacturing new electric vehicles.

It saves time and costs, as less development resources are needed for the OEM. At the same time, the high handling and NVH performance criteria are met due to the long-standing expertise of all involved parties.

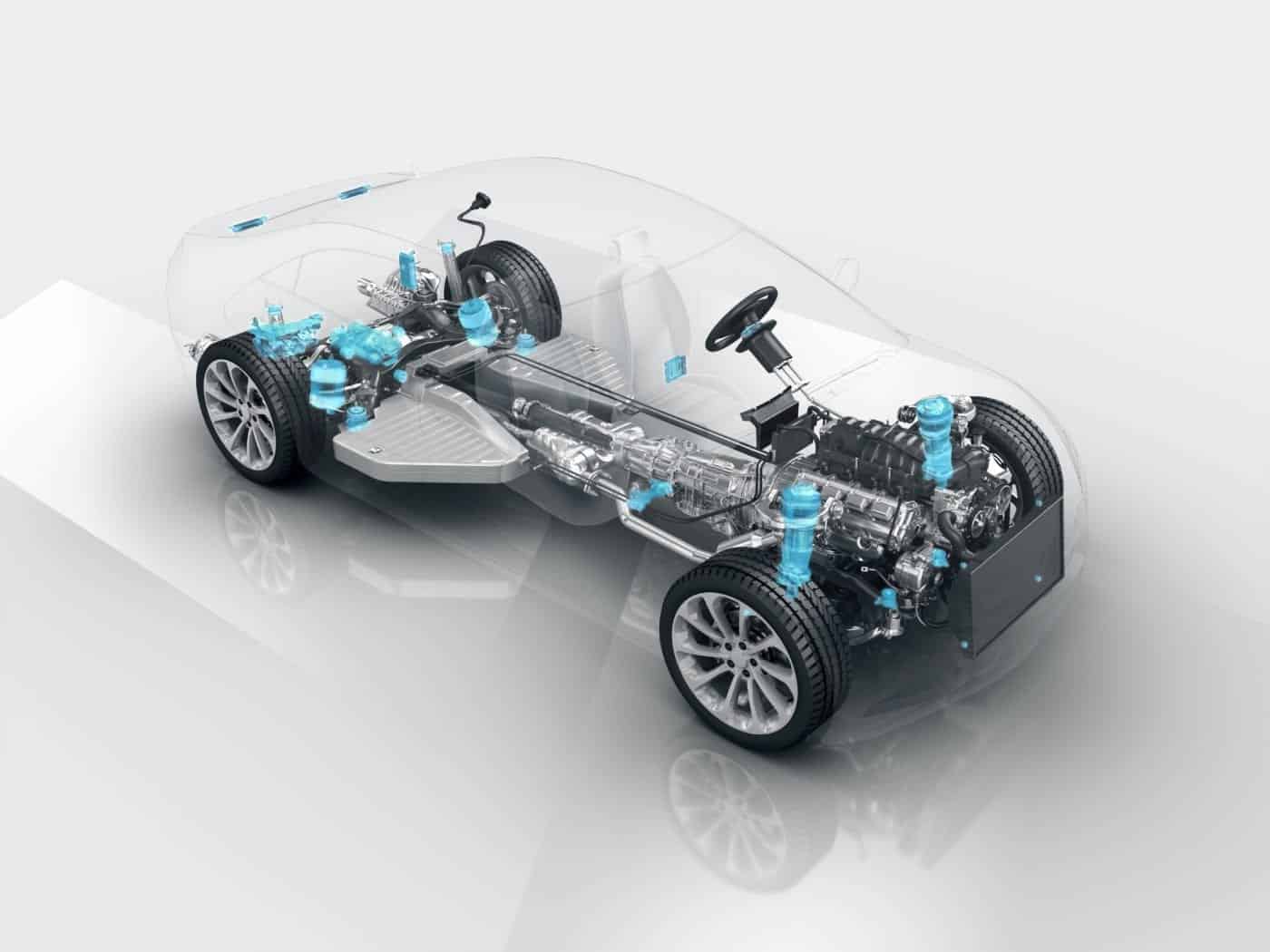

Hybrid Drive Trains

Electrified drive trains like full or plug-in hybrid vehicles further increase the efficiency of internal combustion engines. They combine the convenience of refueling and the maturity of the development of conventional drive trains with the efficiency increase and additional torque of electric motors. Hybrids face the NVH challenges of both drive train concepts – the low frequency excitations of combustion engines and the high frequency excitations of electric motors.

Customized NVH solutions from Vibracoustic address both challenges and provide a comfortable, relaxed and safe ride also in vehicles with electrified drive trains.

Plug-In Hybrid Vehicle

For every vehicle type, size or drive train, we work together with our customers in this fast-paced industry to solve NVH challenges today and support them on their way to mobility concepts of the future.