Darmstadt, April 19, 2023 |

Vibracoustic develops innovative air supply unit bracket with enhanced NVH features

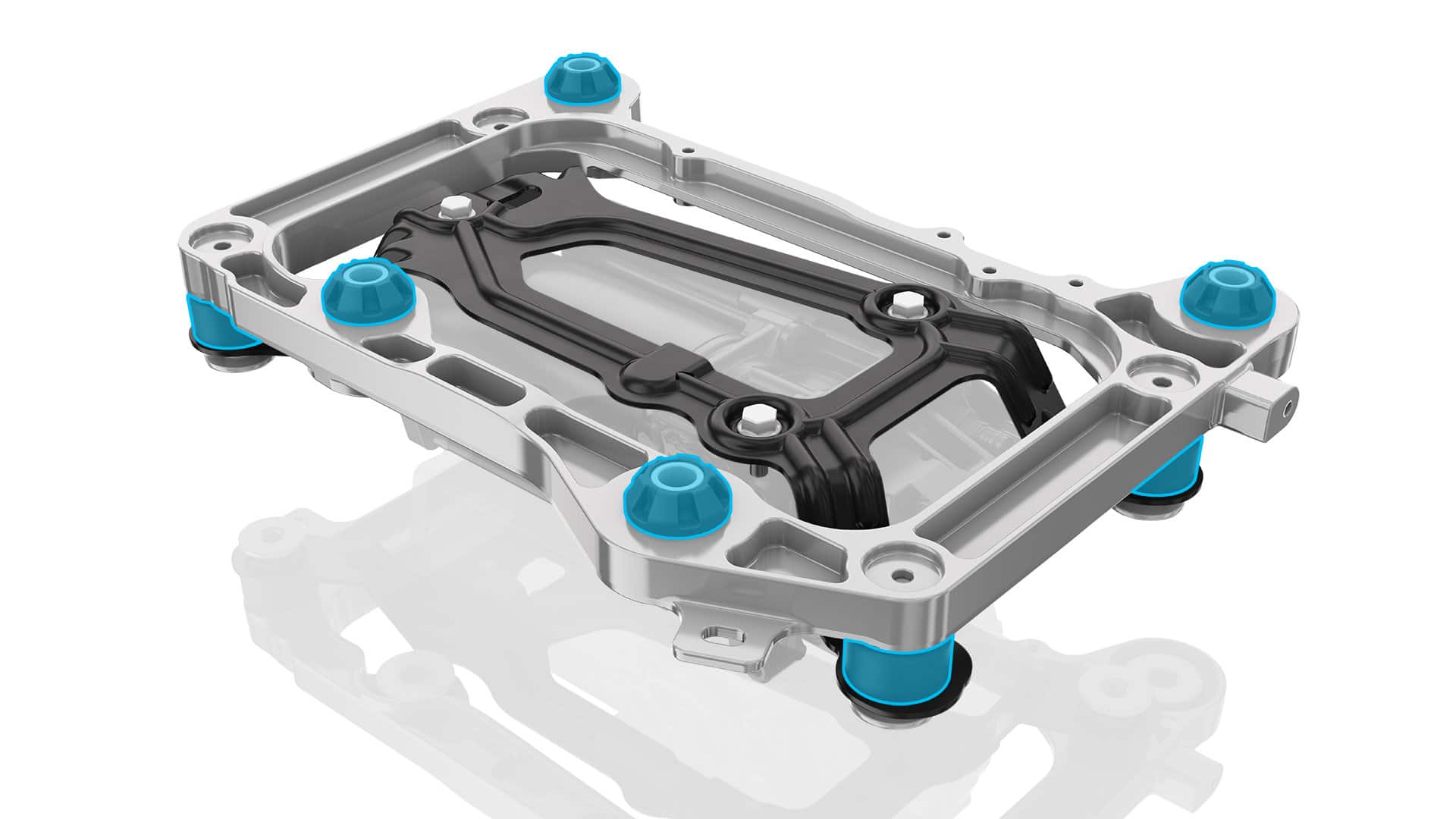

Vibracoustic, a leading global automotive noise, vibration and harshness (NVH) expert, has developed a new tunable bracket for air suspension air supply units (ASUs) that improves NVH performance with radial and axial damping, provides reduced weight and complexity and reduces the resonance caused by the compressor excitations.

Driven by the rise of electrification, the popularity of SUVs, and the overall greater consumer demand for comfort, the market for advanced and innovative air springs is growing rapidly. As a global leader in air springs development and manufacturing, Vibracoustic experts are continuously working on solutions that address modern NVH challenges faced by OEMs.

One of these solutions is Vibracoustic’s new ASU mounting bracket. The air supply unit is part of the complete air spring system and carries the compressor as well as the valve block. The ASU therewith executes the commands from the electronic control unit and de- or increases the air volume in the respective air springs. The newly developed mounting bracket is lighter and more robust than traditional brackets and allows for NVH tuning in all directions, including radial and axial damping, something not possible with the coil springs typically used in such applications.

To address the downsides of coil spring applications – their high resonance responses and the inability to provide a tunable support for radial deflections and excitations – Vibracoustic engineers created an alternative rubber system including bellow-style bushings and bump stops. In developing the right compound, they were able to reach the required stiffness levels while also damping both radial and axial excitations. Additionally, the ‘roll-over’ bellow design of the new bushings allows for high displacement at low strain levels, mimicking the performance of springs. The new material properties aid in maintaining resonance peaks within a reasonable range. This is because the rubber compound demonstrates a dynamic stiffness peak that is up to 60 per cent lower than of a coil spring The potential to independently tune bushing rates in all working directions comes with the added benefit of improved NVH robustness.

Furthermore, Vibracoustic designed the new bushings with modular snap-fit connections for ease of assembly to address OEM needs like simplicity and cost. The team also improved the bracket itself, switching from metal to plastic. This provides damping to further improve system NVH and eliminate aggressive resonance while also leading to weight savings.

Dr Jörg Böcking, CTO at Vibracoustic, commented: “Due to its inherent comfort and suitability for a wide range of applications, air suspensions are becoming an increasingly popular choice for OEMs. Building up on our experience in providing full air springs systems and our understanding of how it interacts with the whole vehicle, we strive to improve all different components. And the ASU bracket is another example of how we optimized our solution to increase the NVH performance and increase the driving comfort. “