The Vibracoustic Energy Efficiency (VEE) aims to achieve our energy and CO2 targets through local measures. Site Energy Managers drive improvement measures, while regional VEE Managers track and evaluate regional initiatives. Additionally, the program has dedicated functions for topics such as green energy, machine specifications, and others. The VEE Committee, which includes members of the Vibracoustic Management Board, regularly review global and site-specific energy-efficiency projects.

The VEE Team tracks continuous improvement initiatives such as energy monitoring, compressed air leakage reduction, heating and cooling controls, start-up and shut-down procedure management, and LED lighting.

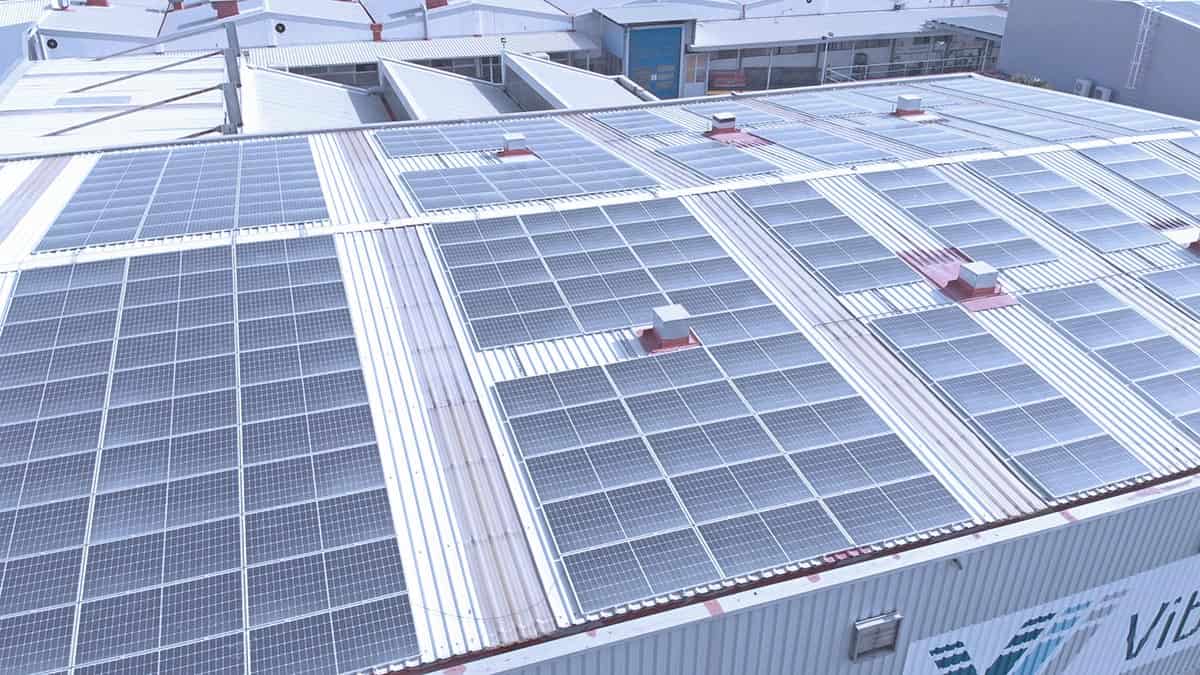

Reducing our emissions also means reducing our energy consumption. We aim to reduce our energy usage every year at all our locations. Our sites are actively tracking and reporting their energy usage each month and are looking at ways to achieve further reductions by installing capacitor banks, actively managing start-up and shut-down processes, and continuously tracking compressed air leakage.

To further reduce our energy consumption, we have also updated our Vibracoustic Machine Specification Book, which gives guidance for the introduction and operation of new equipment and machinery at our plants. The Machine Specification Book includes requirements related to machine start-up and shut-down procedures, energy use monitoring, and maintenance standards to optimize energy efficiency.