Darmstadt, 20. May 2021 |

Vibracoustic reduces complexity and weight with new modular center bearing support

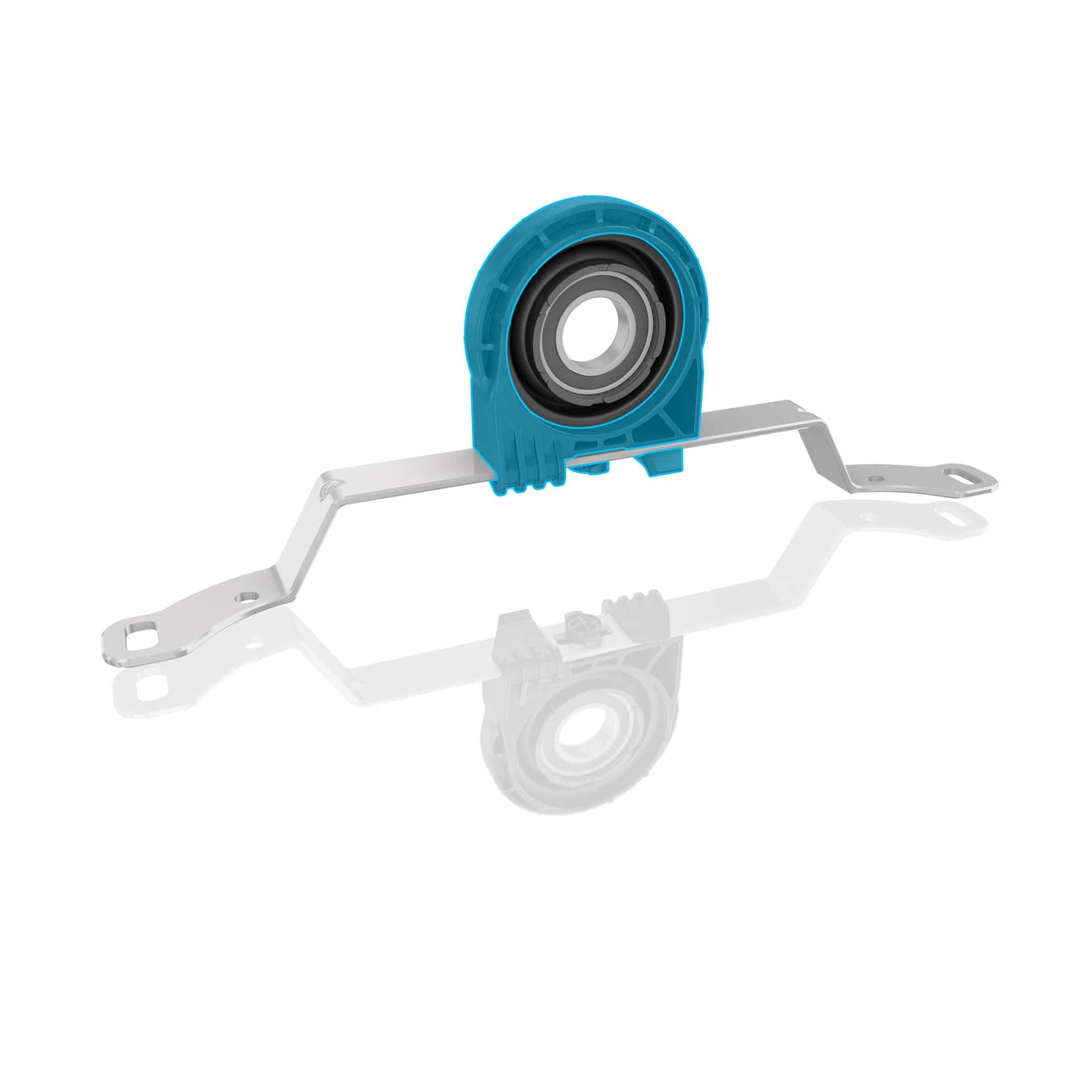

Vibracoustic, a global expert in automotive NVH (noise, vibration and harshness) solutions, has launched a new highly-modular, lightweight center bearing support for prop shaft applications that significantly simplifies assembly and packaging while also improving damping and isolation. Using high-performance plastic housing and rubber isolation, the new center bearing support offers an optimized and highly cost-effective solution for modern passenger vehicles.

Challenging conventional component design, Vibracoustic continues to deliver innovative products that enable lightweighting while enhancing NVH performance. Vibracoustic’s new center bearing support maintains equivalent mechanical performance and packaging volume to a conventional steel or aluminum part, but simultaneously reduces weight by more than a quarter while enhancing NVH.

The Vibracoustic center bearing support is intended to significantly improve ease of installation, enabling increased production efficiency. The metal bracket can be adapted to suit a number of different applications while the plastic housing itself remains the same, making it a versatile and modular solution for OEMs. It simplifies and accelerates assembly thanks to new click connectors developed by ARaymond, an international expert in fastening and assembly solutions. The click connectors eliminate the need for screw connections and help to further reduce total weight.

Internal tests have shown optimized crash performance and fracture toughness and validated part design and material selection.The plastic demonstrated excellent temperature stability and maintained the required mechanical properties within the operating temperature range. The use of plastic in this application also brings NVH benefits, offering significantly better high-frequency damping when compared to an equivalent steel component.

To further optimize its NVH performance, a rubber bushing isolates the bearing from the vehicle chassis. This soft rubber compound and its finetuned geometry offers very high performance-density, meaning it delivers exceptional isolation and axial displacement for such a compact part. Depending on the specific application and vehicle, the compound can be tuned to meet requirements like the damping of the prop shaft eigenmode, while remaining compatible with the standard plastic housing.

Dr. Jörg Böcking, CTO at Vibracoustic, commented: “With increasing demands to reduce emissions, lightweighting continues to be a central focus for the automotive industry. At the same time, manufacturers are looking to reduce assembly complexity and improve packaging to boost production efficiency. Our engineers analyzed conventional center bearing supports and systematically assessed their deficiencies, identifying a number of key areas for improvement and developed a unique solution.”