Weinheim, December 19, 2023 |

Vibracoustic launches NVH technologies for electrified commercial vehicles

Vibracoustic, a leading global automotive noise, vibration, and harshness (NVH) expert, is developing new NVH technologies to equip commercial vehicles with low- and zero-emissions powertrains. Vibracoustic has leveraged its experience and expertise to anticipate the industry’s evolution and created NVH-optimized mounting systems for battery packs, electric motors and fuel cells.

Echoing some of the trends seen in the passenger car market, the commercial vehicle (CV) sector is also entering a period of transition. A heightened focus on alternative powertrains aims to provide more sustainable transportation of goods and people – an important step to support global sustainability goals and reduce emissions in the transportation sector. This change brings numerous unique and complex NVH challenges, from the distinct acoustic character of electric motors and inverters to the additional weight and safety considerations of battery packs. While the use-case for CVs differs substantially from passenger cars, Vibracoustic is already leveraging its experience in NVH management to develop best-suited solutions for CV applications that support the shift in the industry.

Double isolation of high frequency powertrains

The electrification of powertrains in the CV sector, calls for innovative solutions that address the specific challenges they present. With lower weight and higher torque than Internal Combustion Engine (ICE) counterparts, electric motors produce a wide range of frequency, including high-frequency excitations of more than 600Hz, which can be disturbing for the human ear, particularly when coupled with the other noises which are left unmasked be the quieter powertrain.

Vibracoustic engineers identified the specific requirements for e-motor mounting and developed solutions that meet isolation and decoupling requirements of CV Original Equipment Manufacturers (OEMs). One solution, specifically developed to promote comfort while addressing the high frequency excitations in electric commercial vehicles is the so-called double isolation. It uses two layers of rubber components: one between the e-motor and subframe, the other between the subframe and chassis. This means that the subframe is used as a blocking mass whose inertia – with the correctly designed vibration technology system – can drastically reduce the transmission of higher-frequency vibrations or structure-borne noise. The use of double isolation is particularly relevant for application in commercial vehicles such as e-busses where a high number of passengers are exposed to those excitations.

Battery Packs: Heavy load, crash protection, vibration isolation

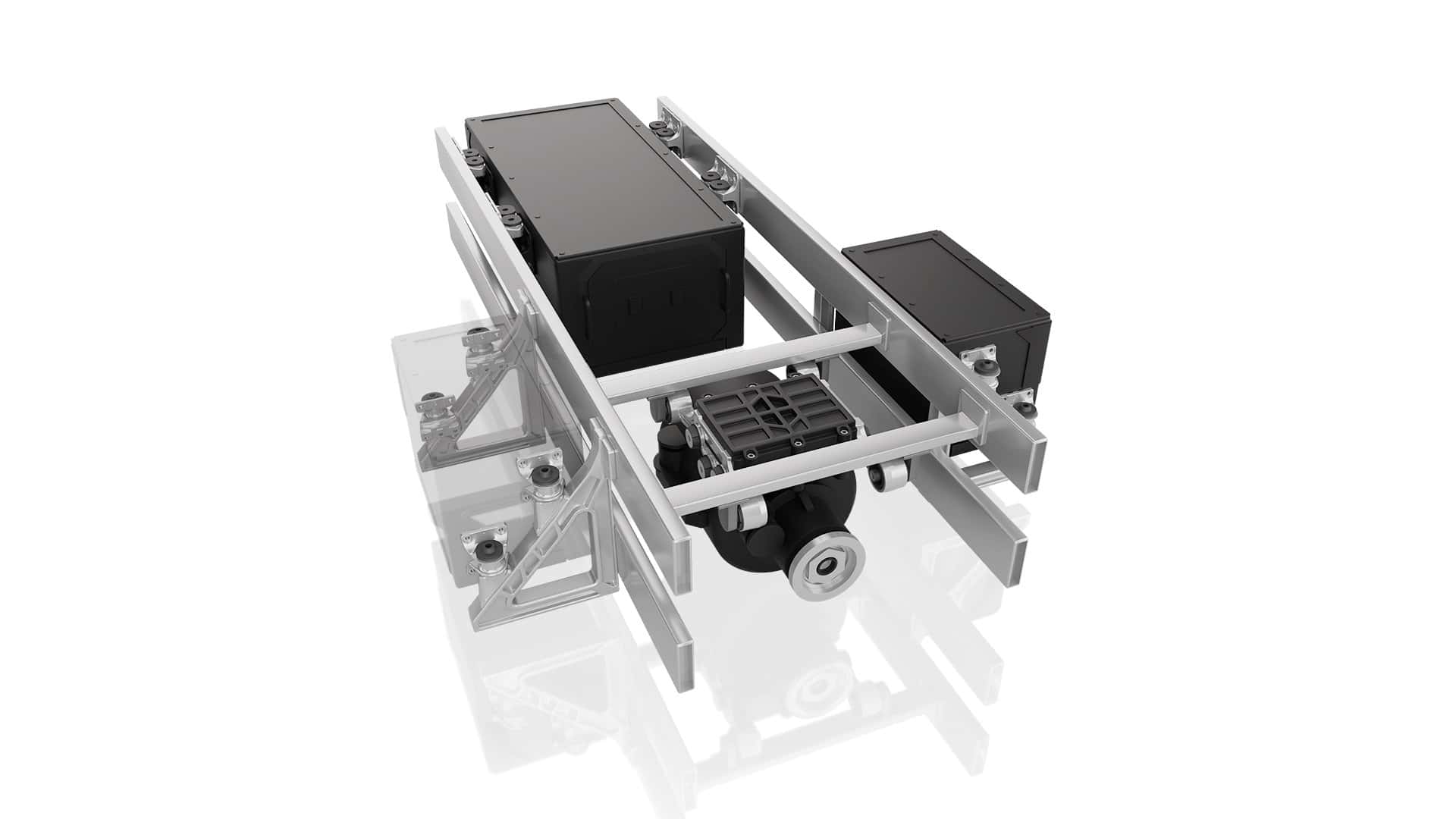

Whether considering a fully electric, hybrid or fuel-cell CV powertrain, mounting and protecting the battery packs effectively is a critical consideration. These packs can weigh from 100 to 6,000kg, with significant challenges linked to weight, mounting, crash loading and NVH. Vibracoustic has designed comprehensive mounting solutions to meet OEMs’ needs for design, load and durability.

The requirements and considerations for battery pack mounting are multi-faceted. The mounts must minimize the transfer of road excitations to the battery pack, including compensation for any deflection or movement of the chassis or vehicle structure. They must enhance structural integrity and overall frame stiffness, especially if the battery is an integrated element of the chassis. Vibracoustic’s mounts are specifically designed to accommodate high travel, thereby ensuring stability and protection in operational conditions. Furthermore, the battery mounts play an important safety role as they help to reduce forces in an impact, acting as a robust energy absorber and dissipator.

Peter Binner, Head of Business Unit Commercial Vehicles at Vibracoustic, commented: “As the commercial vehicle sector begins to electrify and decarbonize, our OEM and Tier 1 customers are benefitting from Vibracoustic’s expertise in solving NVH challenges. The shift in the commercial vehicle sector brings some new challenges, however, we are well equipped to support our customers along this journey. With our solutions for electric motors, battery packs, and fuel cells we are able to support our customers to deliver greener and quieter vehicles for a more efficient commercial transportation future.”