Drive Shaft Dampers

Reduce or eliminate torsional vibrations and natural frequencies at the drive shaft

Geometry optimized for low frequencies, high radial stiffness and durability

Designed for best balancing characteristics, inertia/weight ratio and small packaging

Compound optimized for high temperature and temperature stability as well as low tolerances

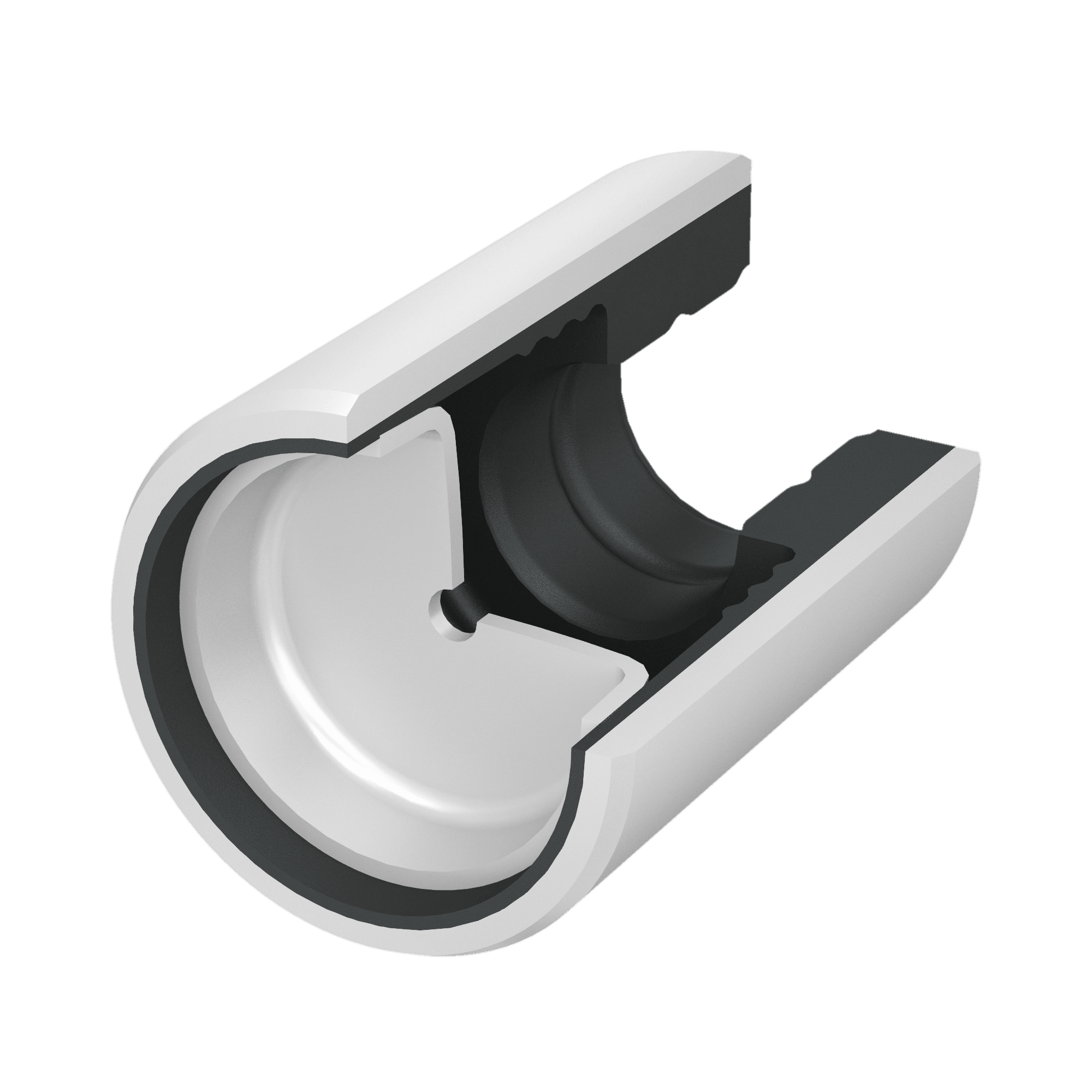

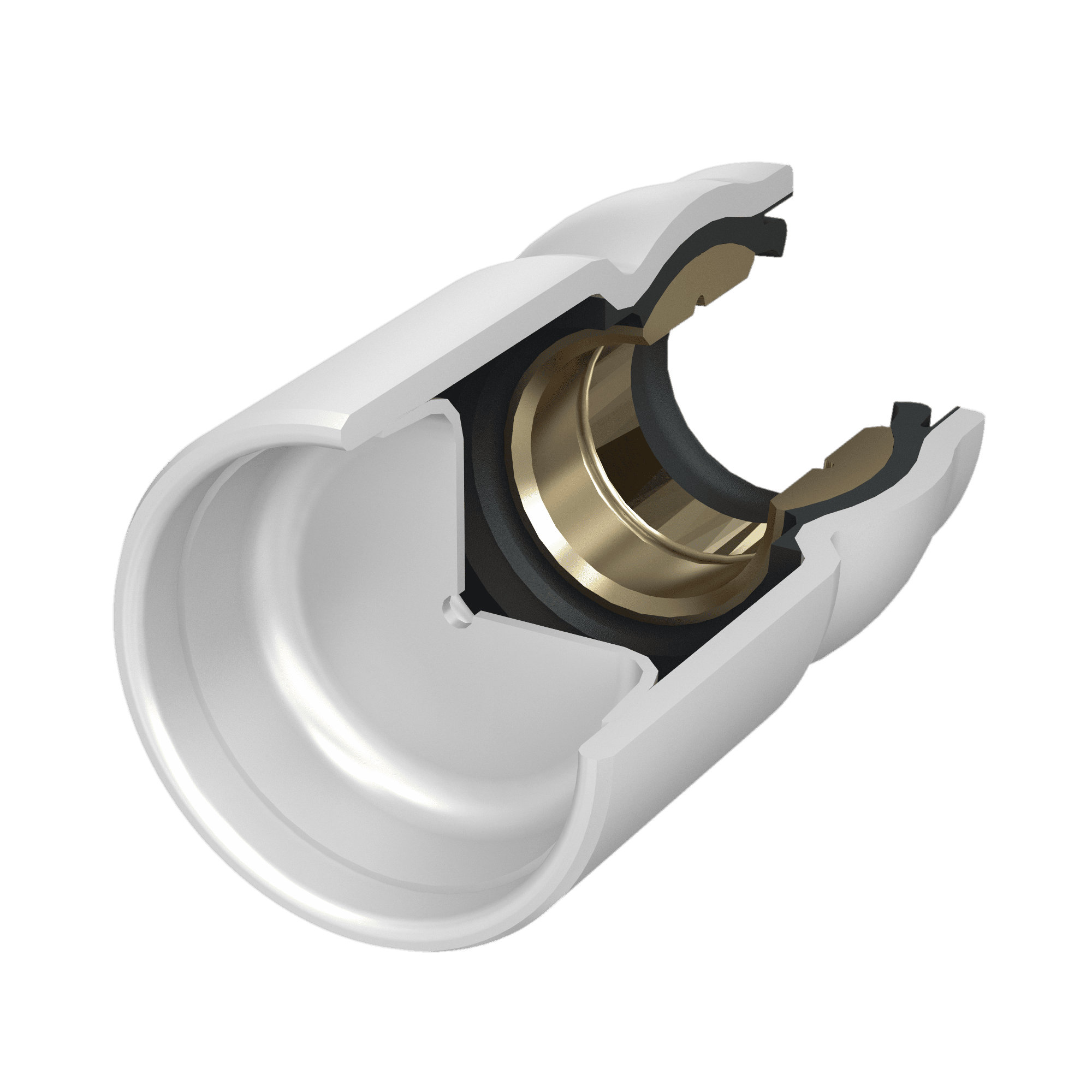

Drive shaft dampers reduce or eliminate torsional vibrations and natural frequencies that are transferred from the motor to the drive shaft. The elastomeric element, mostly rubber, is optimized for NVH requirements, high temperatures and temperature stability, as well as low tolerances. In addition, the rubber geometry can be optimized for low frequencies, high radial stiffness and durability.

A drive shaft damper consists of a hub, an elastomeric element and an inertia ring. The inertia ring design is optimized for the best balancing characteristics, inertia/weight ratio and small packaging requirements. For cost reasons it is recommended to use sheet metal parts for the hub and cast iron for the inertia rings.