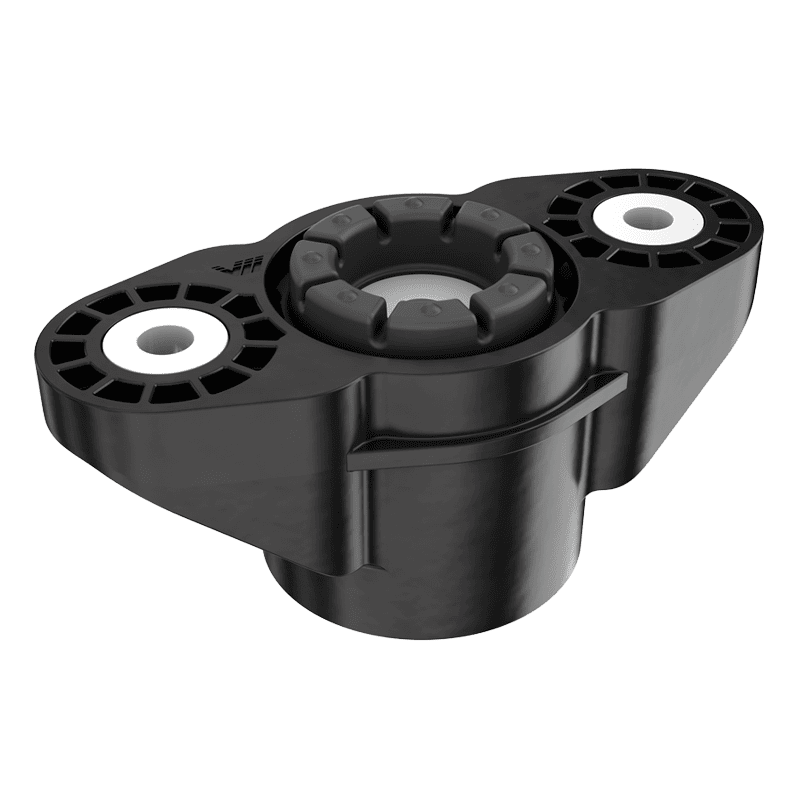

Chassis Bushing for EVs

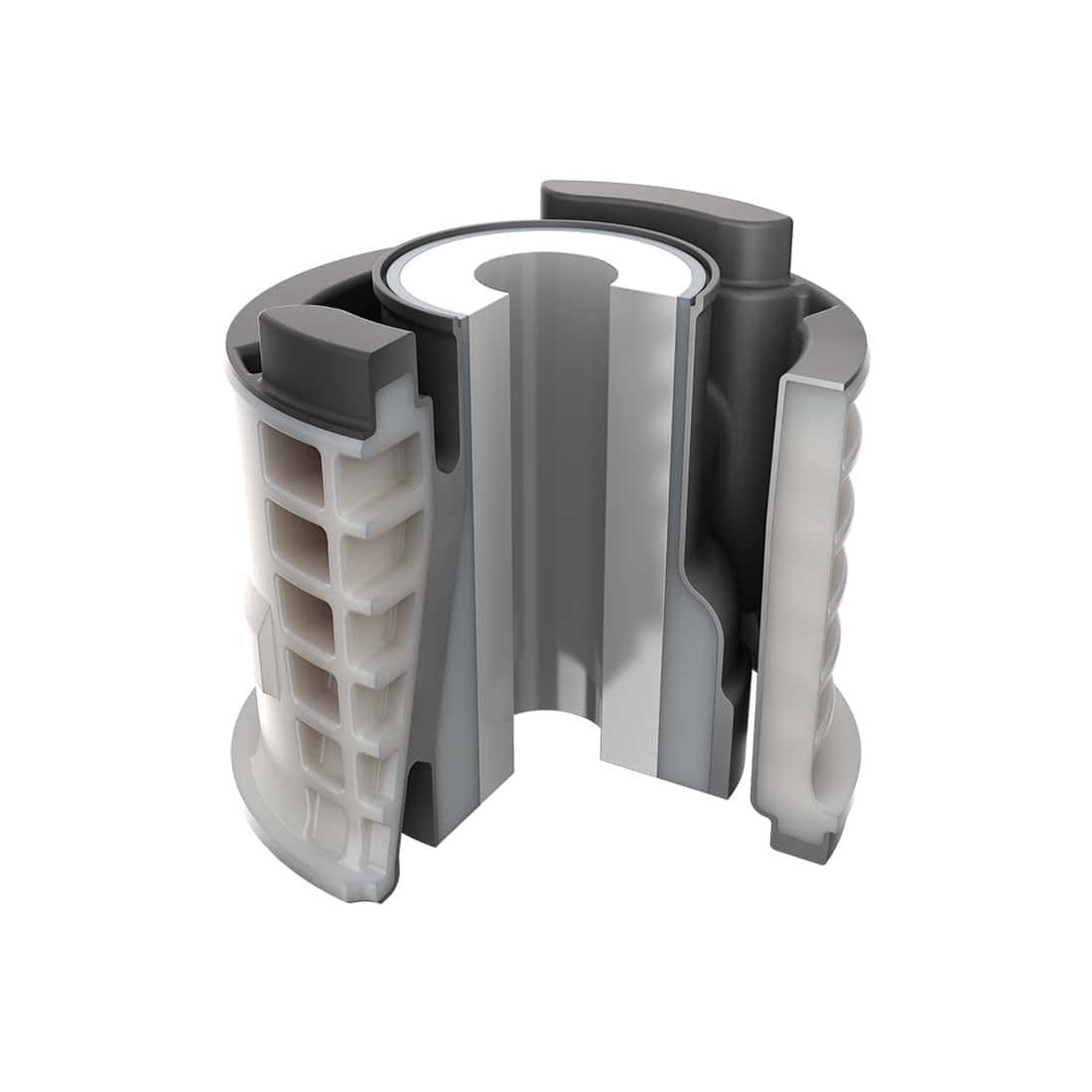

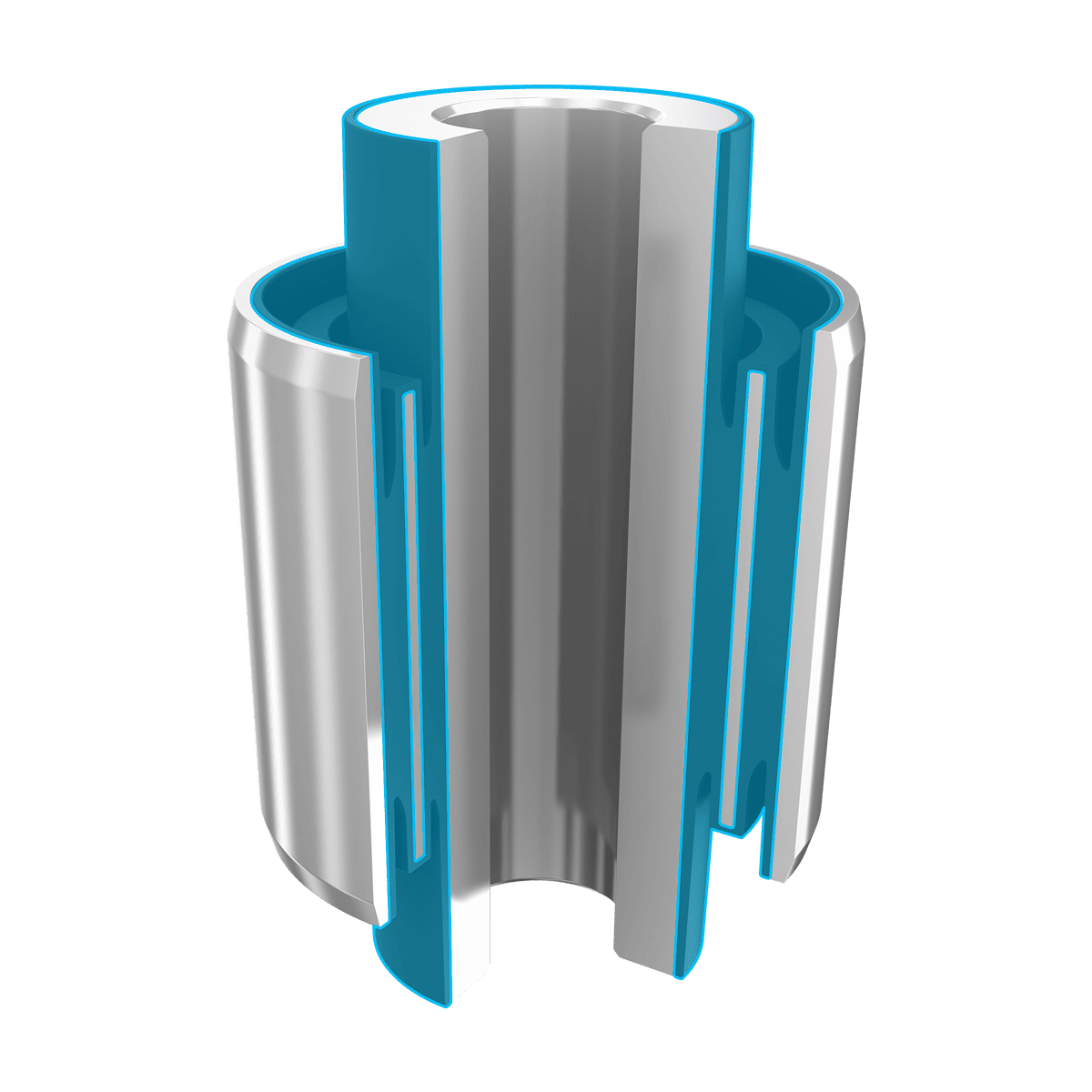

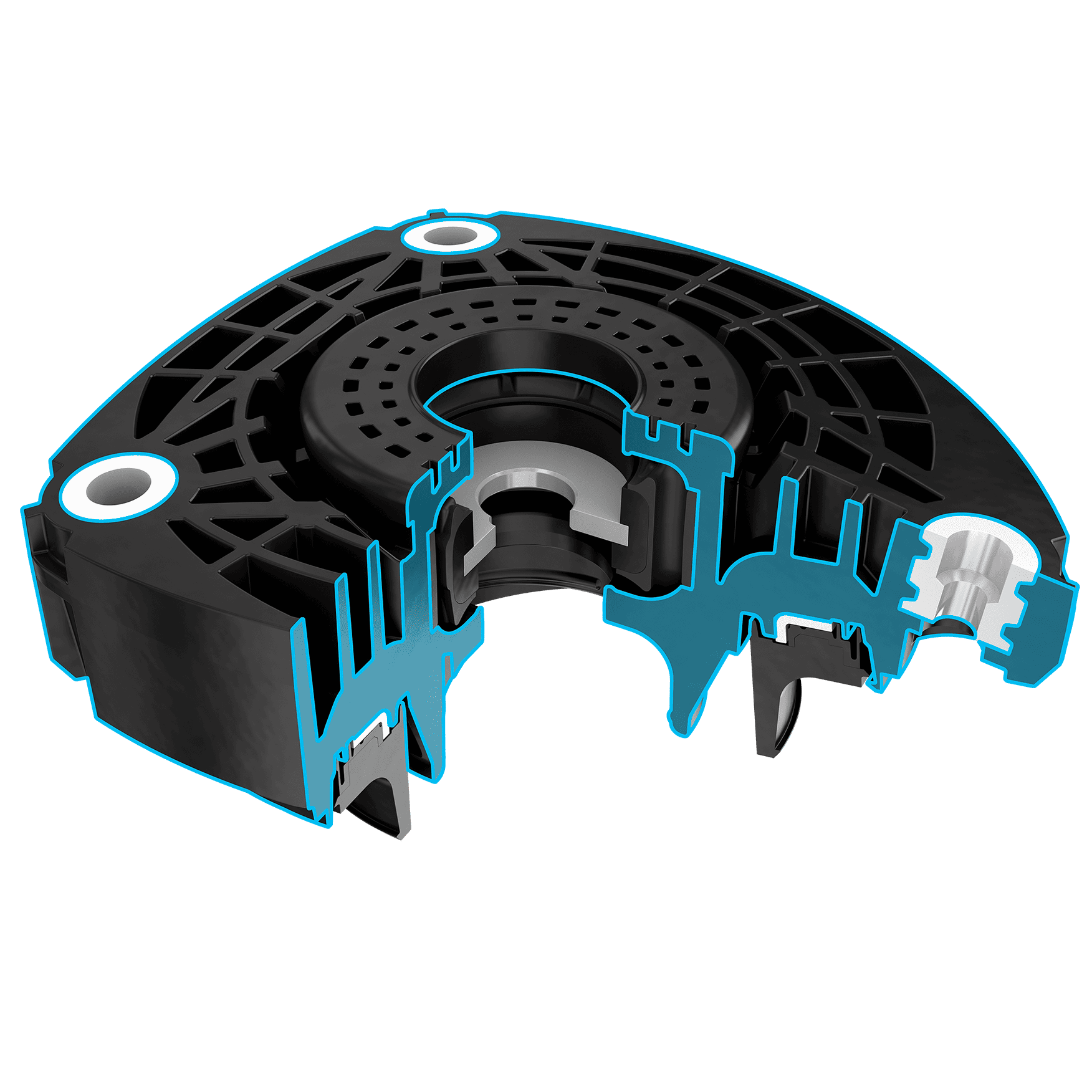

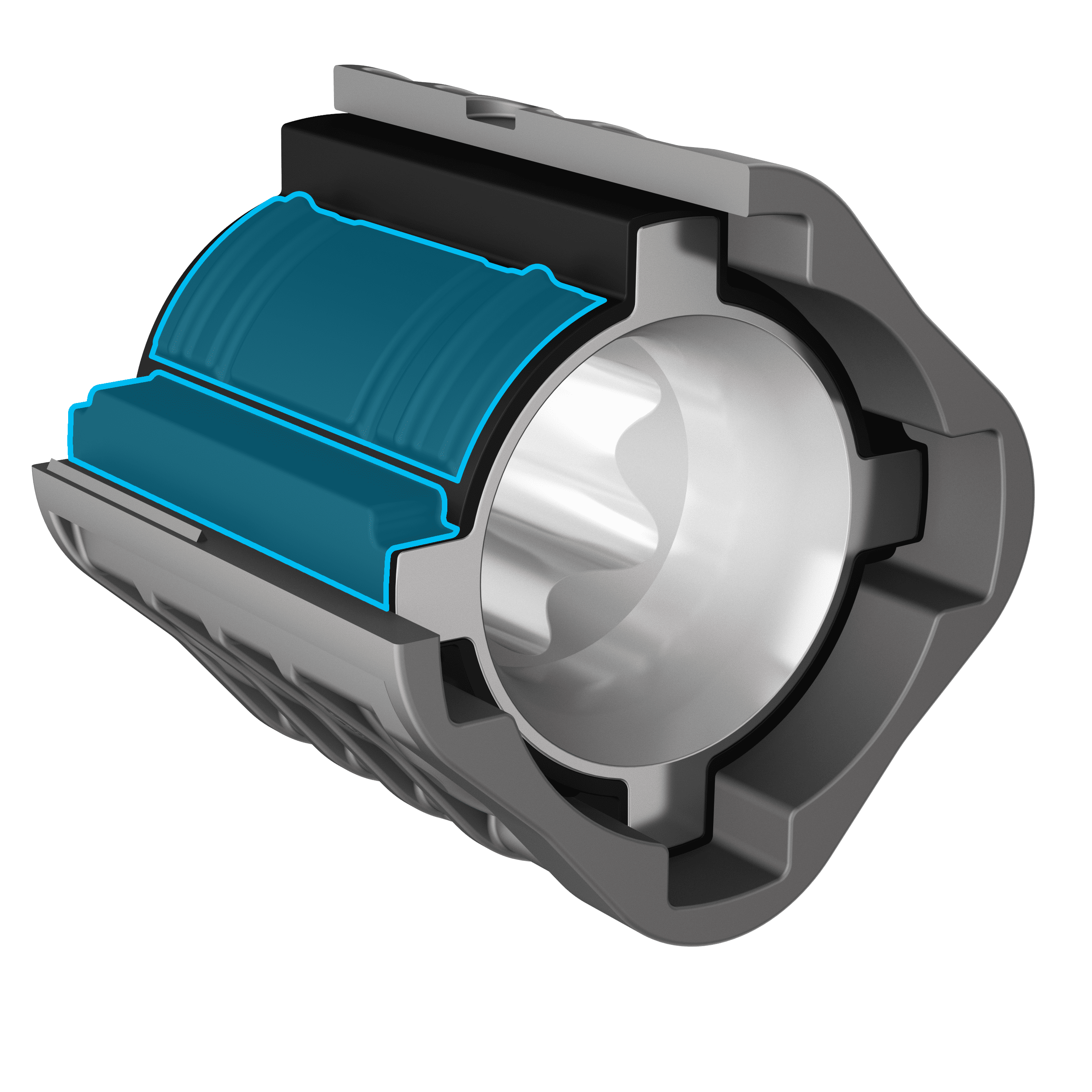

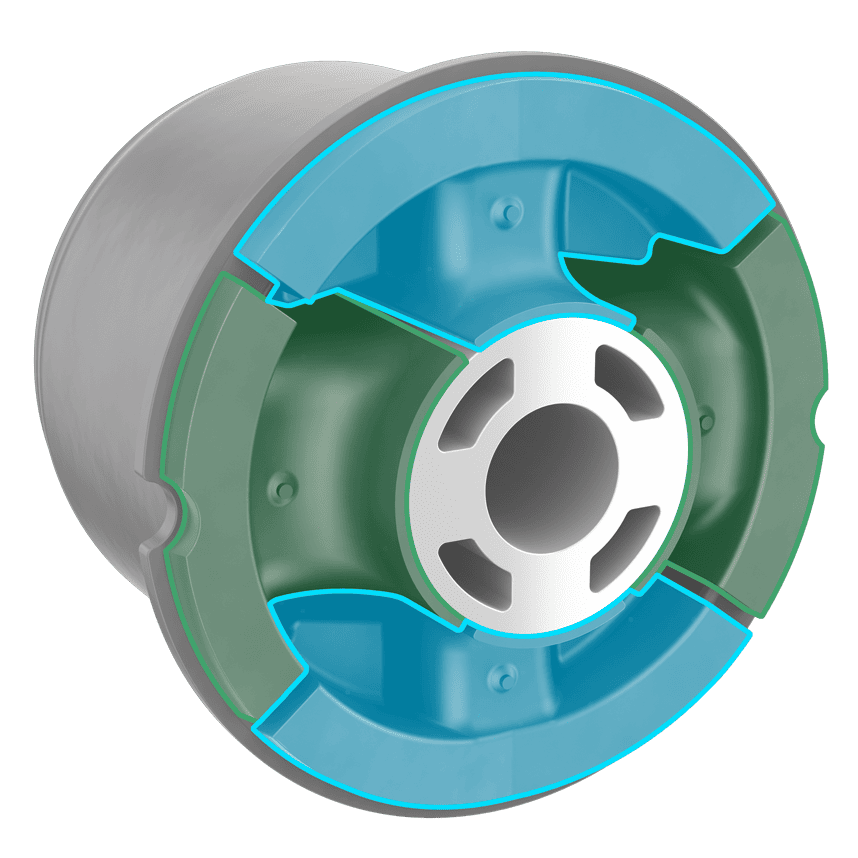

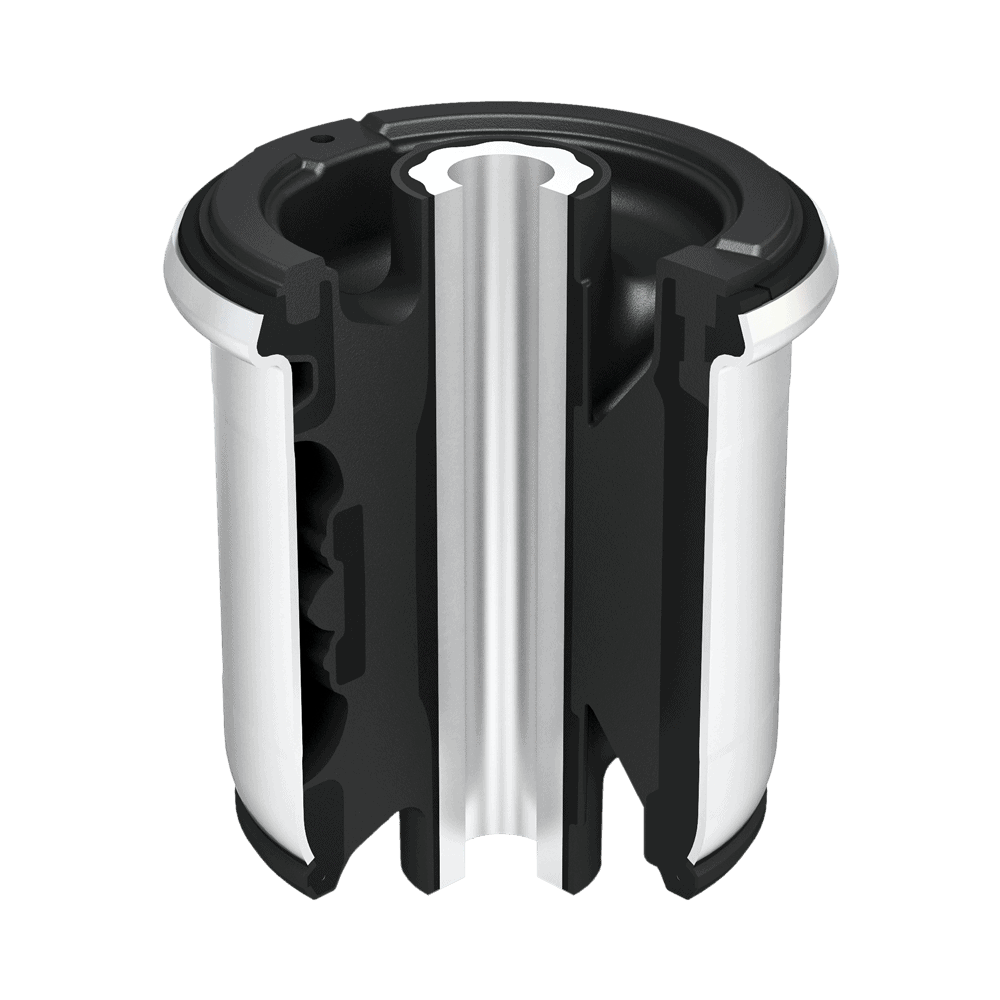

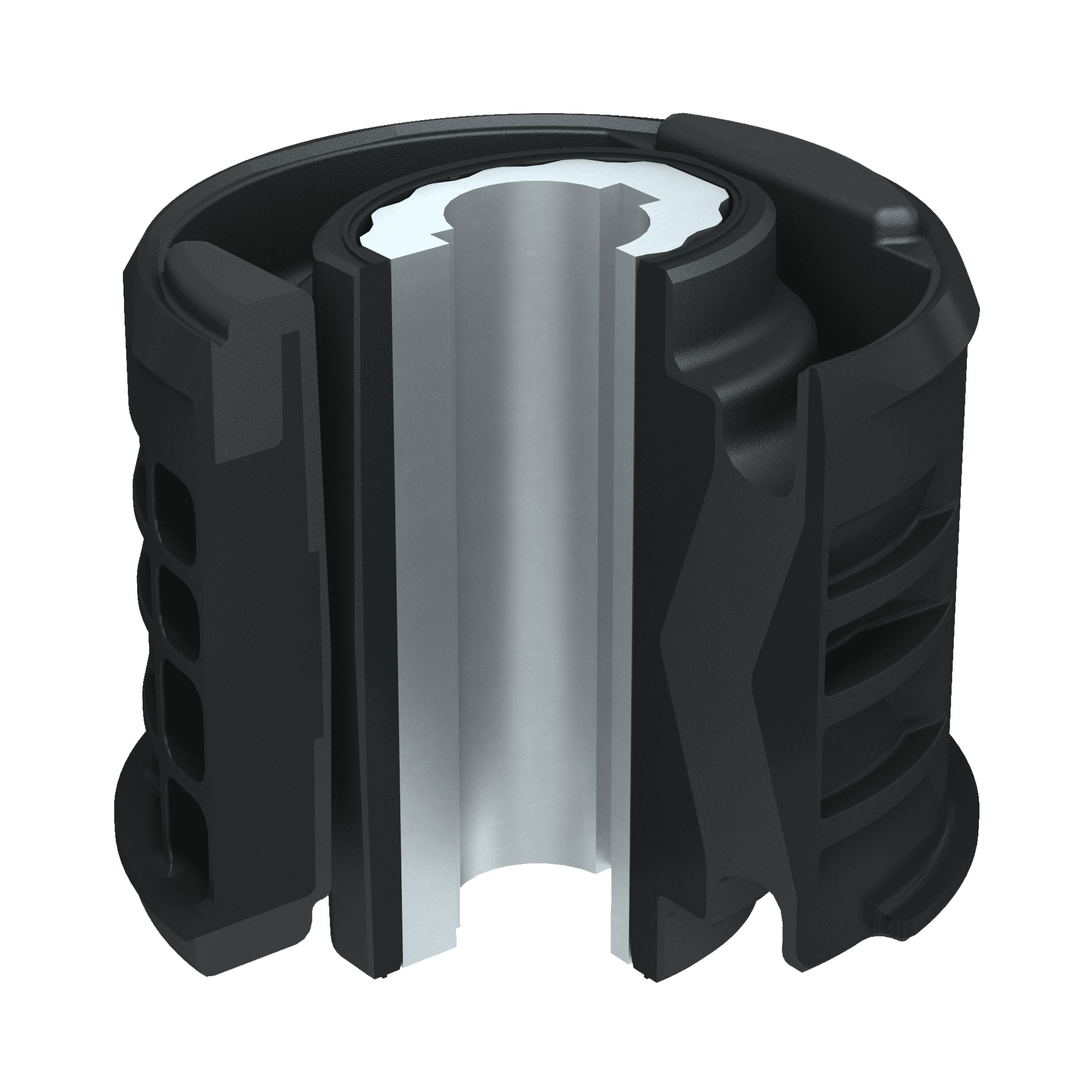

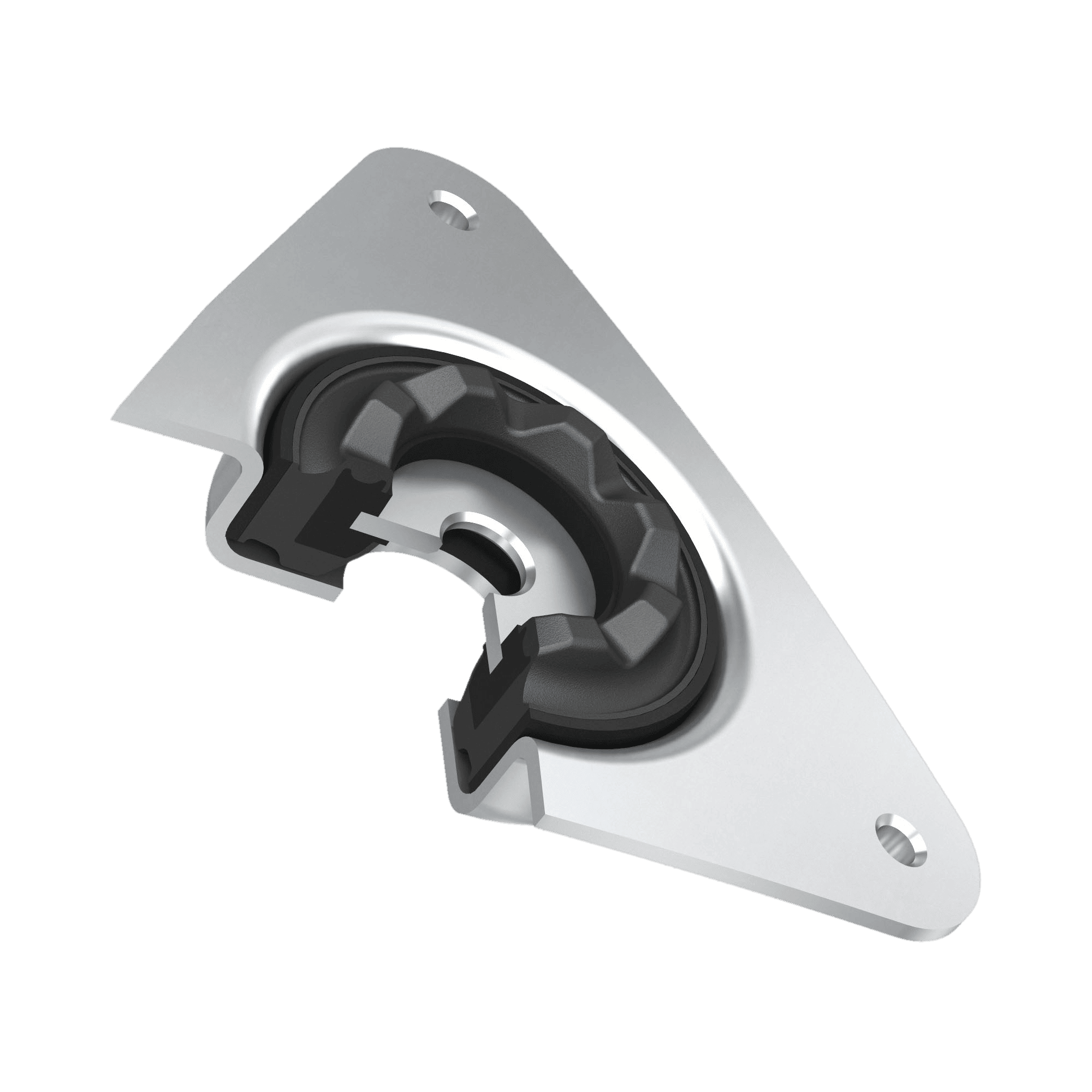

Designed to improve the dynamics, durability, noise management in BEVs with optimized design and material.

Designed to better handle common BEV excitation frequencies.

Increased durability for higher suspension pre-loads.

Low hardening rubber compound optimized for BEV.

New bushing design for BEV NVH management.

Battery electric vehicles (BEVs) are generally heavier than their internal combustion engine (ICE) equivalents. This has substantial implications for chassis control and NVH management, with higher maximum loads, higher suspension pre-loads and greater durability demands for all components involved. The chassis bushings for EVs have been designed to improve the dynamics, durability, noise management and ride quality of BEVs.

These optimized chassis bushings are tuned to handle the increased vehicle weight and higher preloads found in BEVs, while also ensuring great NVH performance. This is critical to occupant comfort and ride quality. Furthermore, BEV powertrains are substantially quieter than the ones found in ICE-powered vehicles. This presents an important challenge, since sounds previously masked by the ICE like road noise, chassis excitations, and in-cabin noises, become far more noticeable. This essentially calls for solutions with better high frequency isolation characteristics.

The chassis mounts employ optimized rubber compounds with low-hardening characteristics to better address and mitigate the frequencies encountered. The improved design allows the solution to better handle dynamic load (while driving), as well as static preload (while stationary).