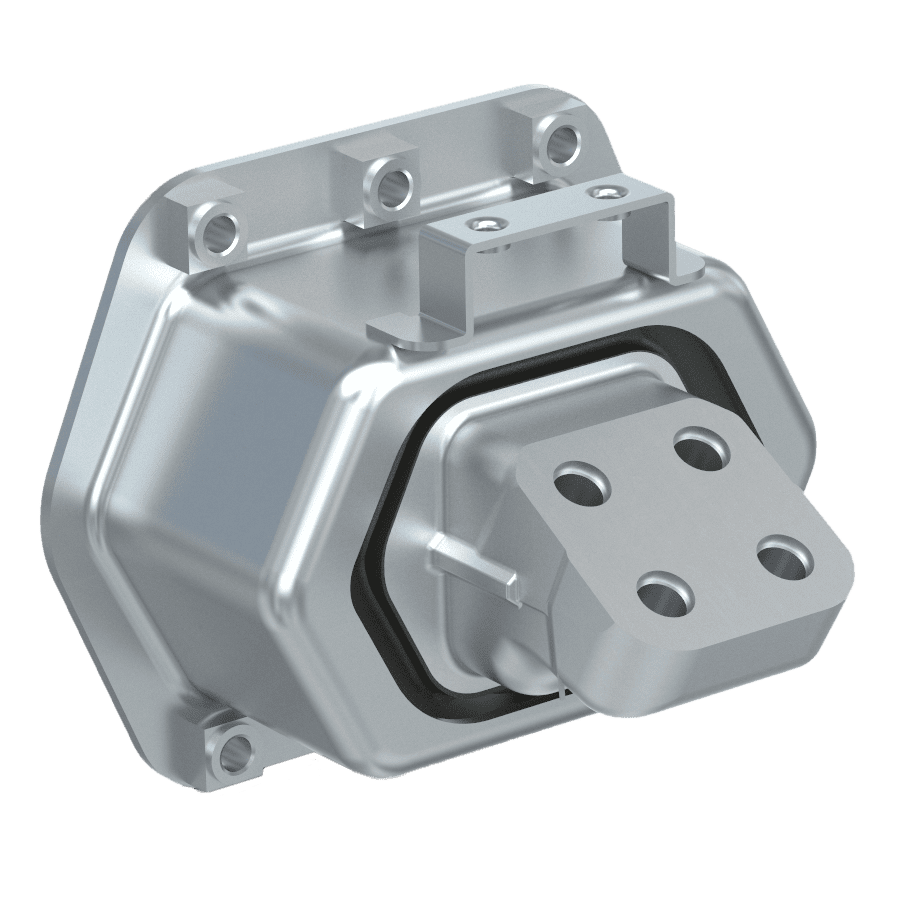

Transmission Mounts

Limit maximum deflections and provide vibration isolation from low to high frequencies

Weight and cost-optimized metal components

Bolting points for easy assembly

Fixture for screw connections

Pre-stressed rubber compound

Transmission mounts carry the static and dynamic loads of the drive train of trucks and are an important factor for vibration isolation from low to high frequencies. The progressive stiffness limits the maximum deflections during shifting, breaking and accelerating while maintaining low basic stiffness for good isolation. The aluminum components and small packaging result in weight and cost-efficiency.

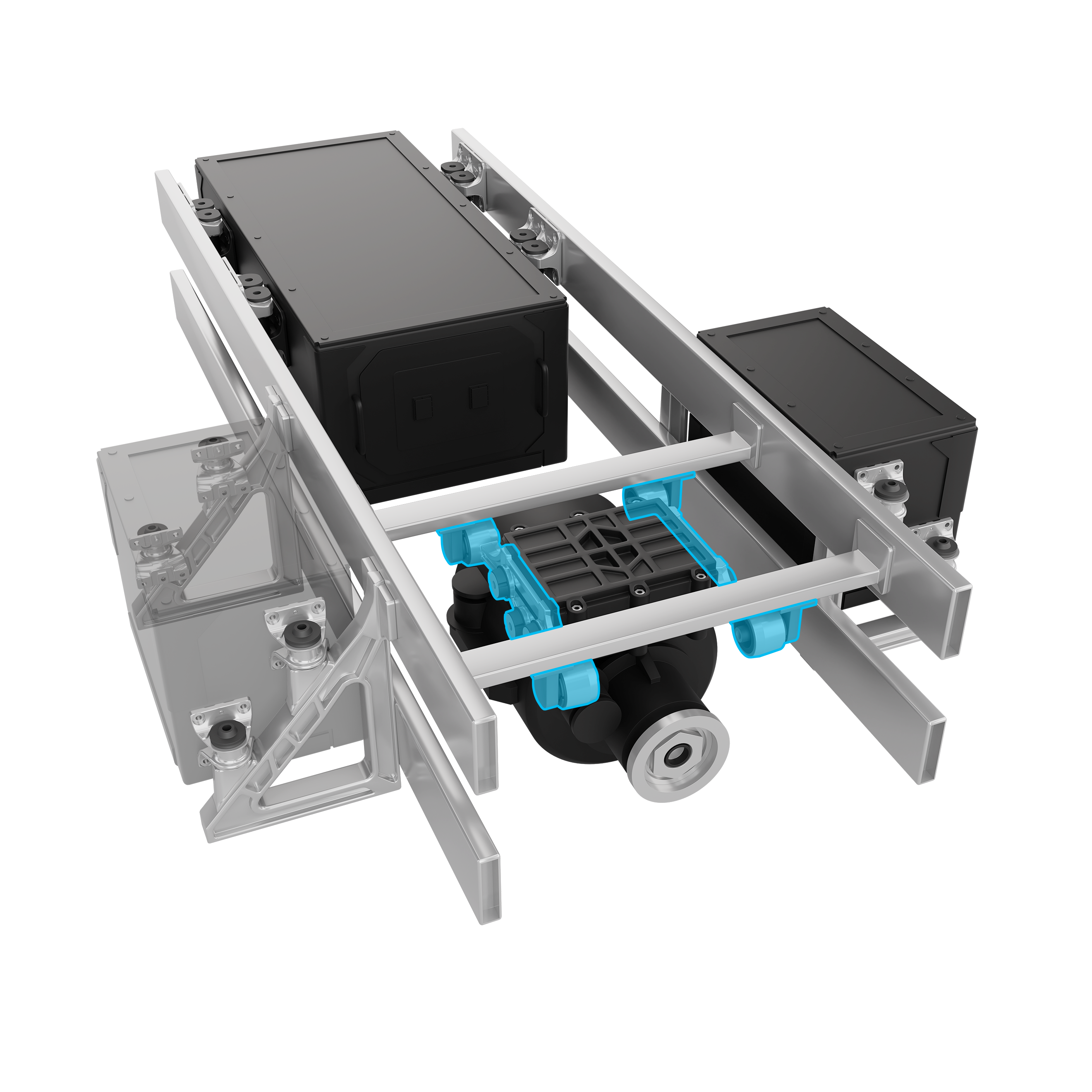

Transmission mounts are typically installed at the connection of the motor and the transmission. Exposed to the high static load of the drive train, they need to provide high durability. This is achieved by using aluminum for the metal components and a temperature-optimized rubber compound.

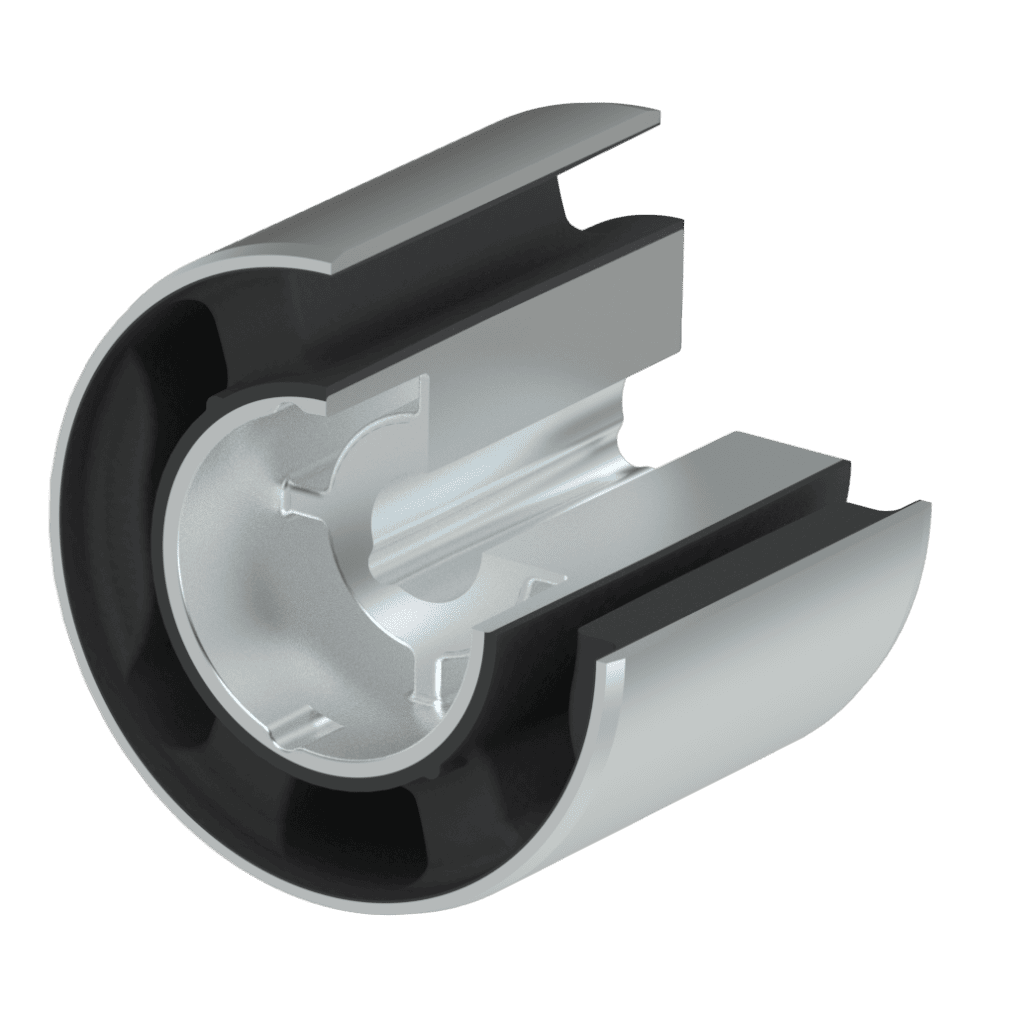

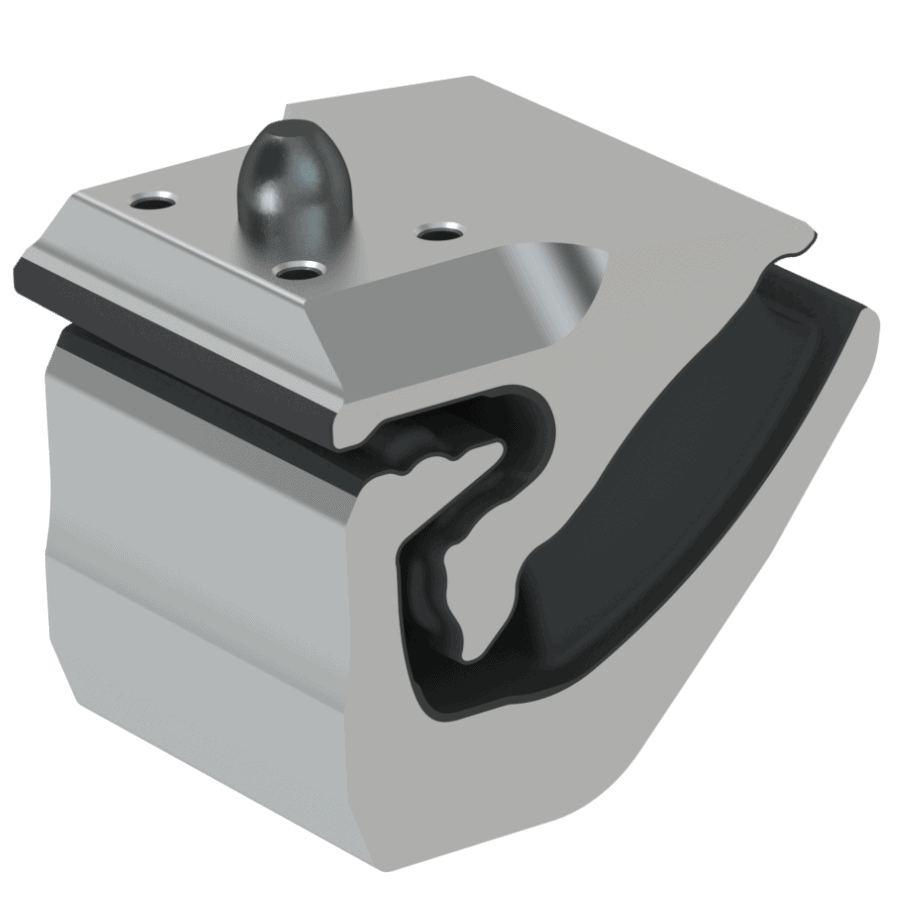

The rubber compound between the metal components is pre-stressed to the weight of the engine and transmission. The result is that the static load is already carried, and the movement of the rubber component is limited, resulting in high durability.

The specially developed natural rubber compound provides optimal NVH performance. It offers a progressive stiffness, which limits the maximum deflections of the engine while shifting, breaking and accelerating. Furthermore, the low basic stiffness for vibration isolation increases comfort and stability.

Using die-casted aluminum and a special design, the transmission mounts are weight and cost efficient and offer reliable performance in optimized packaging. Providing screw connections for the cables and insulation of the truck as well as bolting points secure the easy assembly.