Double Isolation of high frequency powertrains

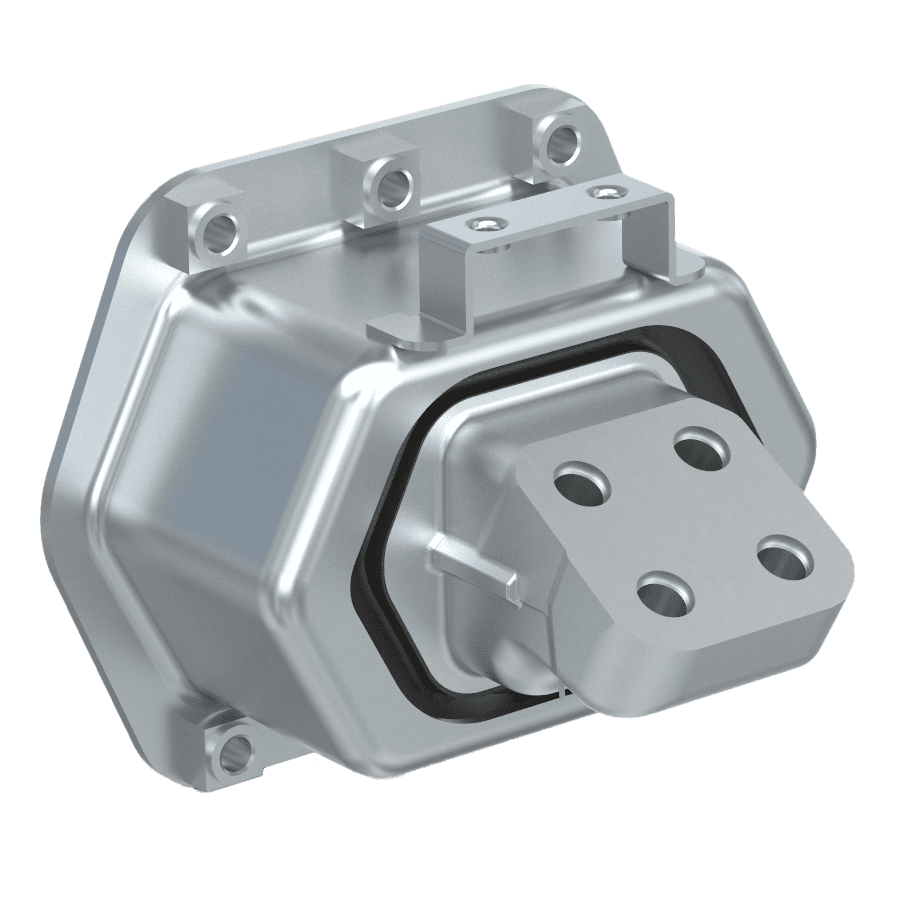

The innovative double isolation system addresses the unique NVH complexities of commercial vehicles equipped with electric motors – especially e-buses.

Increases comfort while addressing high-frequency excitations

Uses two levels of isolation, meeting isolation and decoupling requirements

Ideal for commercial vehicles with passengers

Reduces the transmission of higher-frequency vibrations and structure-borne noise

As the commercial vehicle (CV) sector continues toward electrified powertrains, new NVH challenges are emerging. With lower weight and higher torque than their Internal Combustion Engine (ICE) counterparts, electric motors produce a wide range of excitation frequencies. This includes high-frequency excitations of more than 600Hz, which can be disturbing for the human ear. This effect is compounded by other noises that become apparent in the first place due to the relative silence of the electric drivetrain.

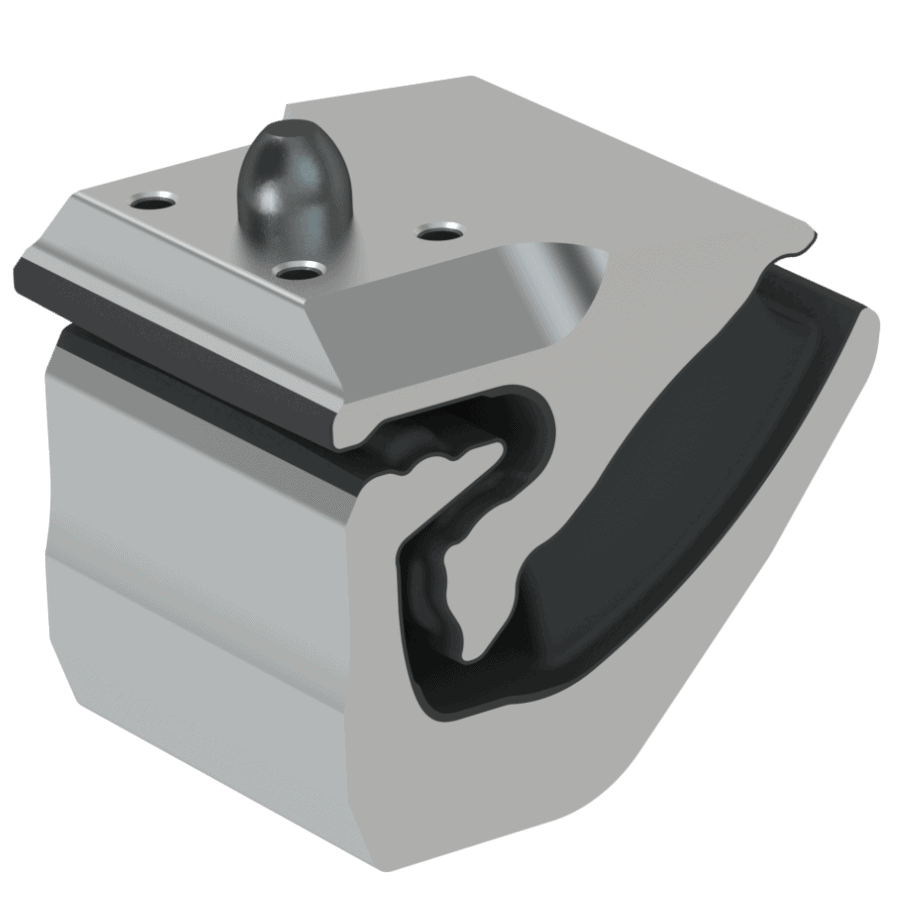

Vibracoustic engineers have identified the specific requirements for optimum e-motor mounting, with a focus on isolation and decoupling. As a result, a mounting solution for electric motors was designed to promote comfort while addressing the high frequency excitations in electric commercial vehicles.

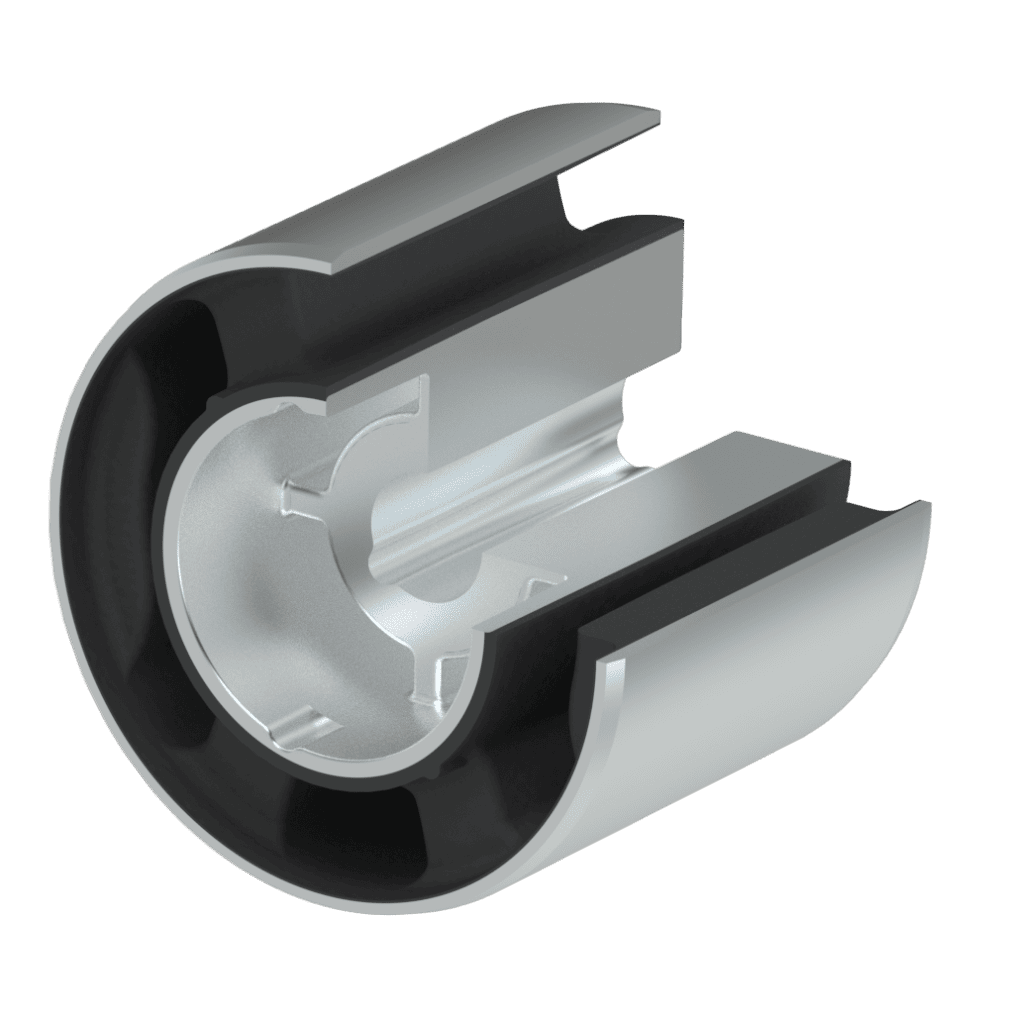

Vibracoustic’s Double Isolation uses two layers of rubber between key components. The first is between the e-motor and subframe, and the second is between the subframe and chassis. This setup uses the subframe as a ‘blocking mass’. With a correctly designed and tuned system, the subframe’s inertia can drastically reduce the transmission of higher-frequency vibrations and structure-borne noise.

The use of Double Isolation is particularly relevant for e-buses and other commercial vehicles where the comfort of passengers is an important consideration.