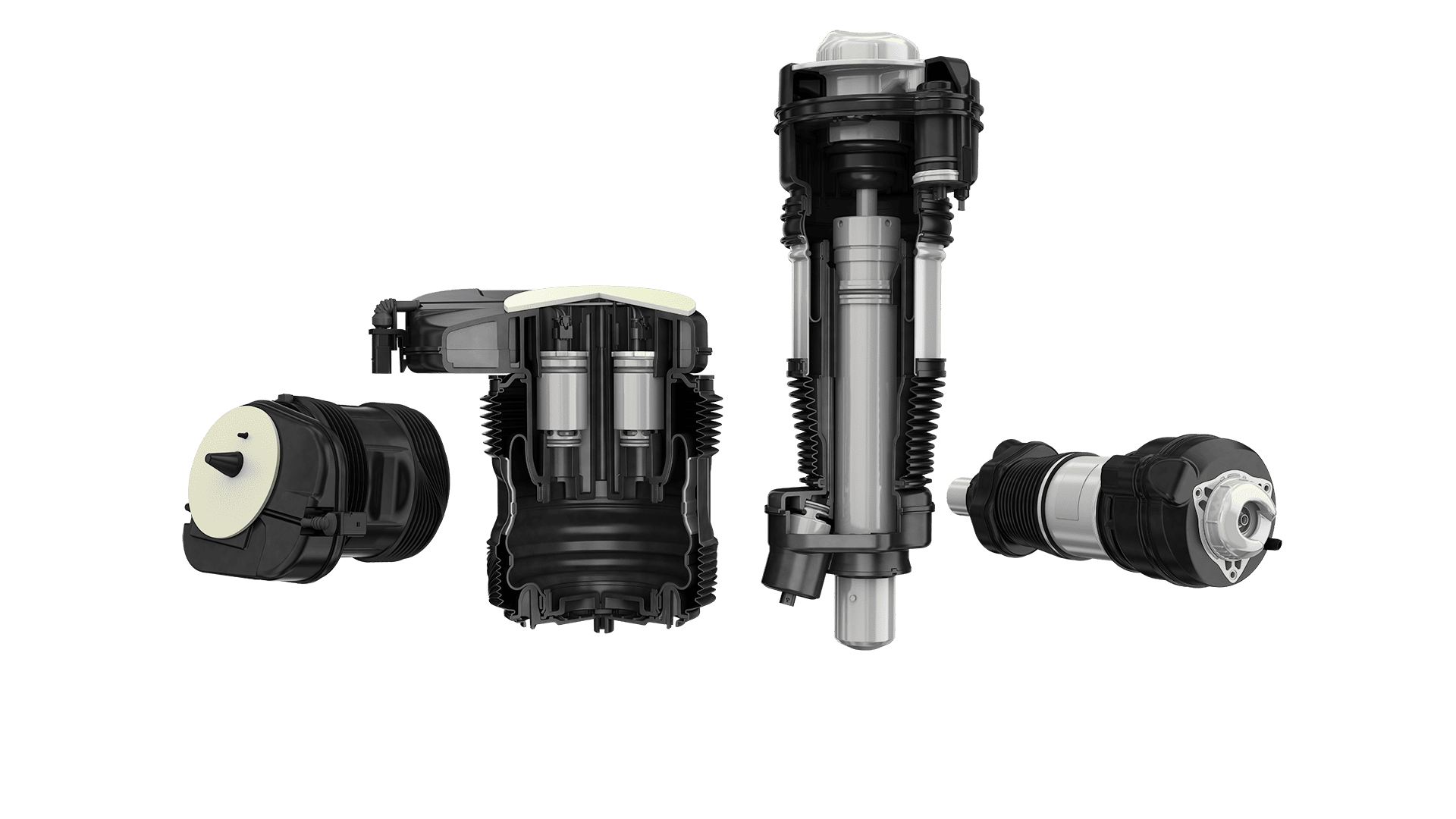

Switchable Three-Chamber Air Springs

Resolve the conflicting objectives of comfort and good driving dynamics

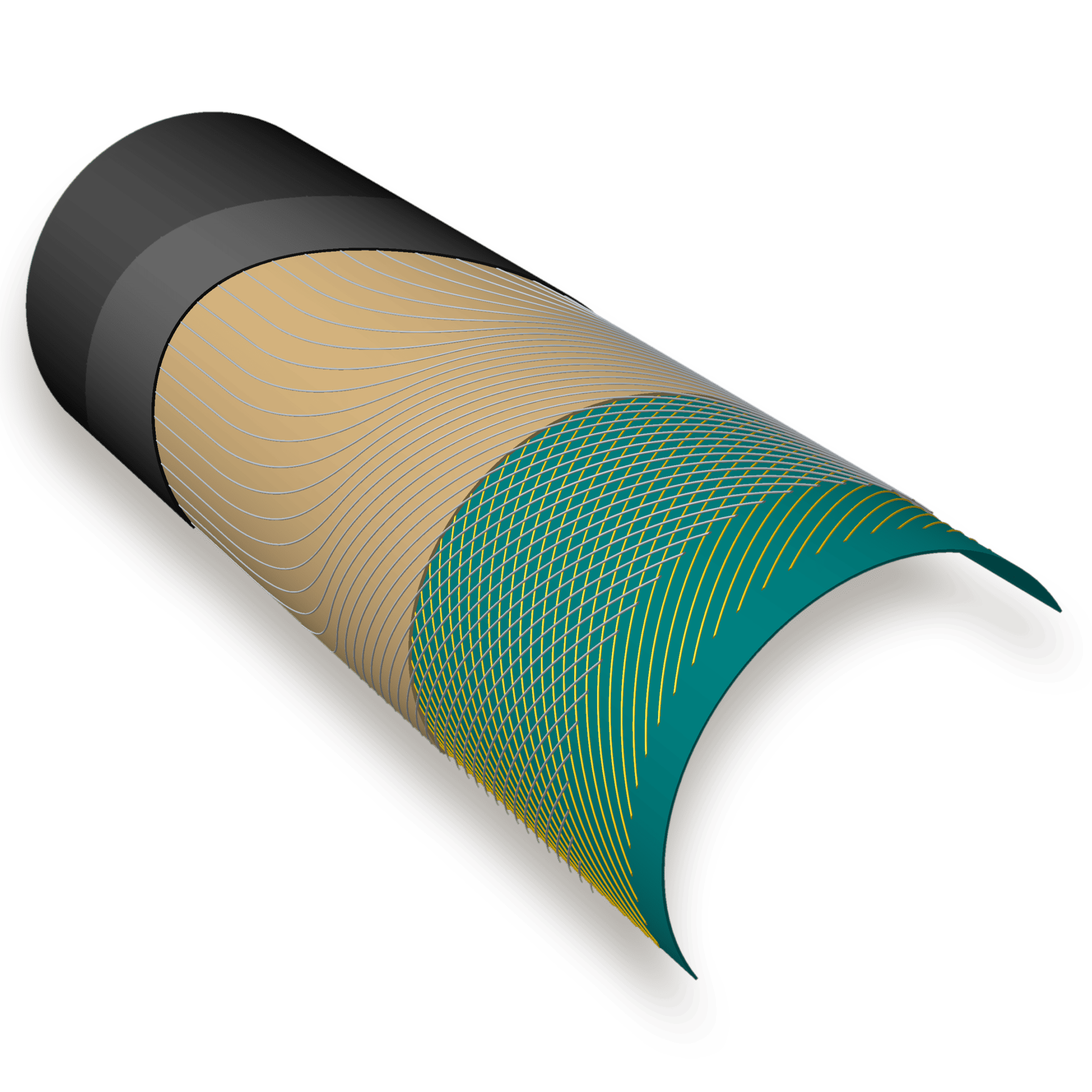

Hot gas welding allows easy creation of volume chambers

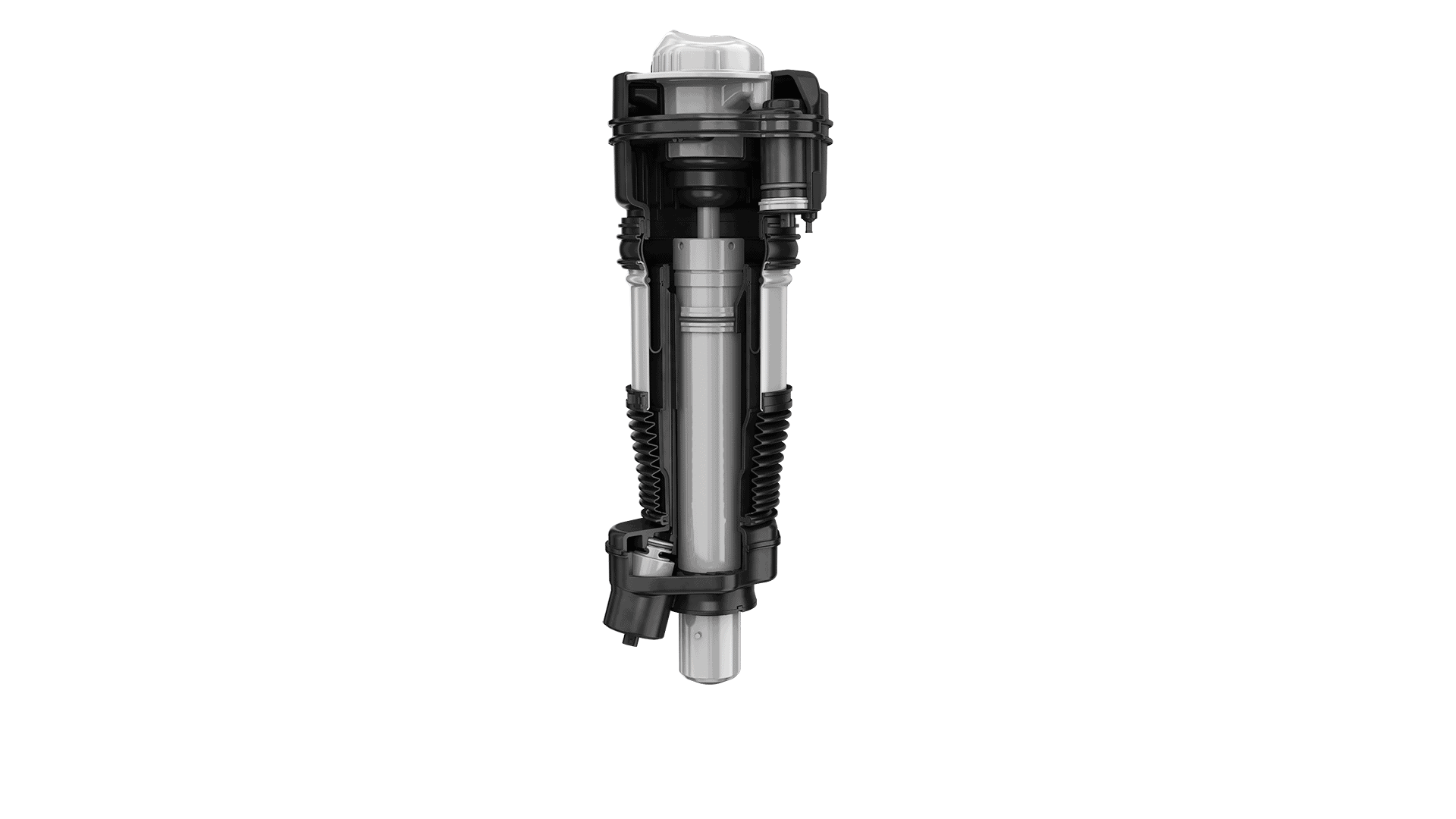

Electric switching valve for dynamic switching of volume

Electric switching valve for dynamic switching of volume

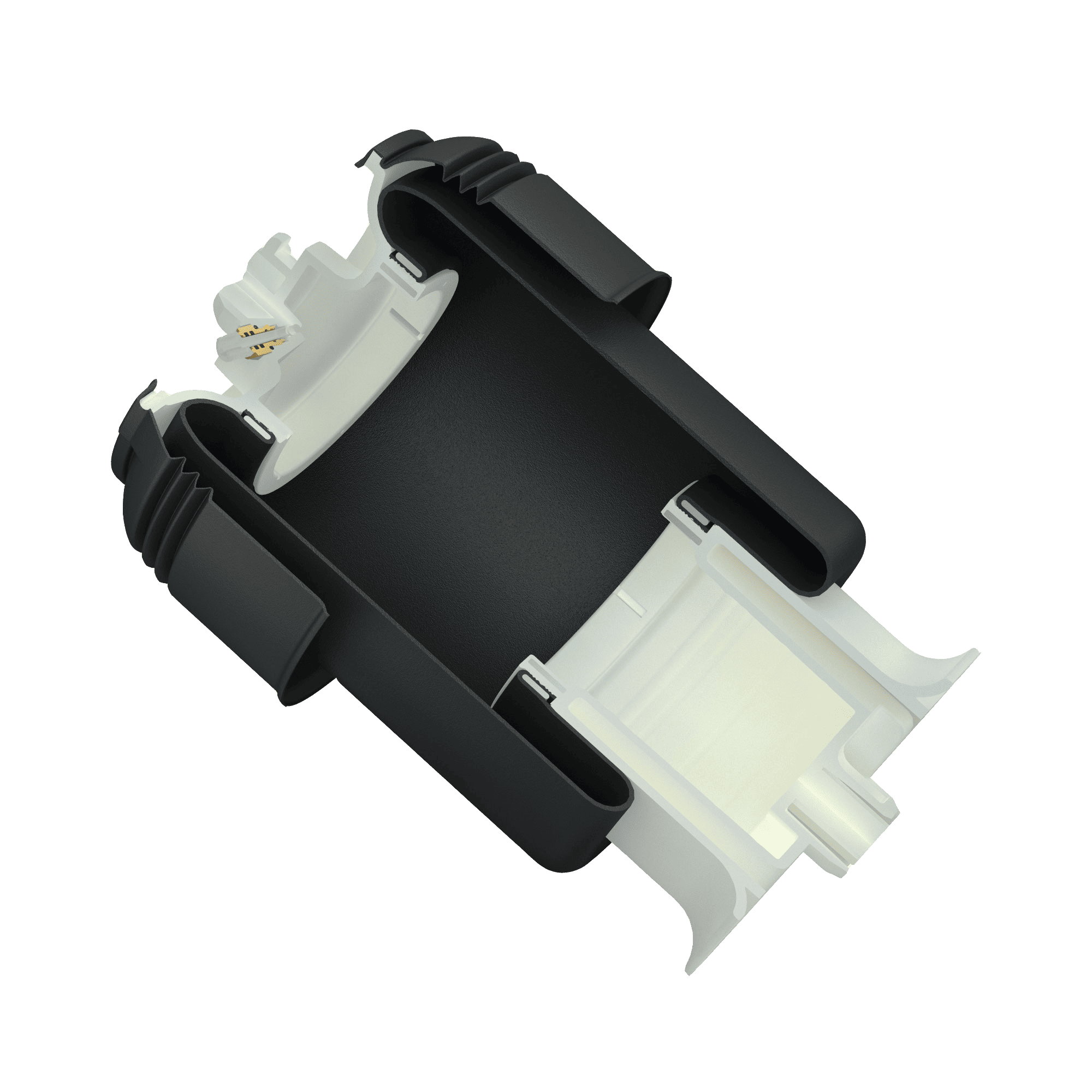

Hybrid aluminum and plastic pot

To resolve the conflicting objectives of comfort and excellent driving dynamics, Vibracoustic has developed switchable air springs with a three-chamber concept for light vehicles. By switching individual air chambers on and off using smart controls, the air springs can be set to four different stiffness levels, depending on the driving situation. This makes driving more comfortable or more dynamic, while improving safety.

Air spring applications at the rear axle or on both axles are becoming increasingly popular for electric vehicles. Air springs enable to control the levelling of the car. This enables optimized aerodynamics at high speeds as well as airflow guidance beneath the car. The latter is especially important for electric vehicles, since it facilitates the efficient passive cooling of battery packs, which are predominantly positioned in the floor area Besides that the air springs support to keep a minimum ground clearance to secure the batteries in bad road conditions.

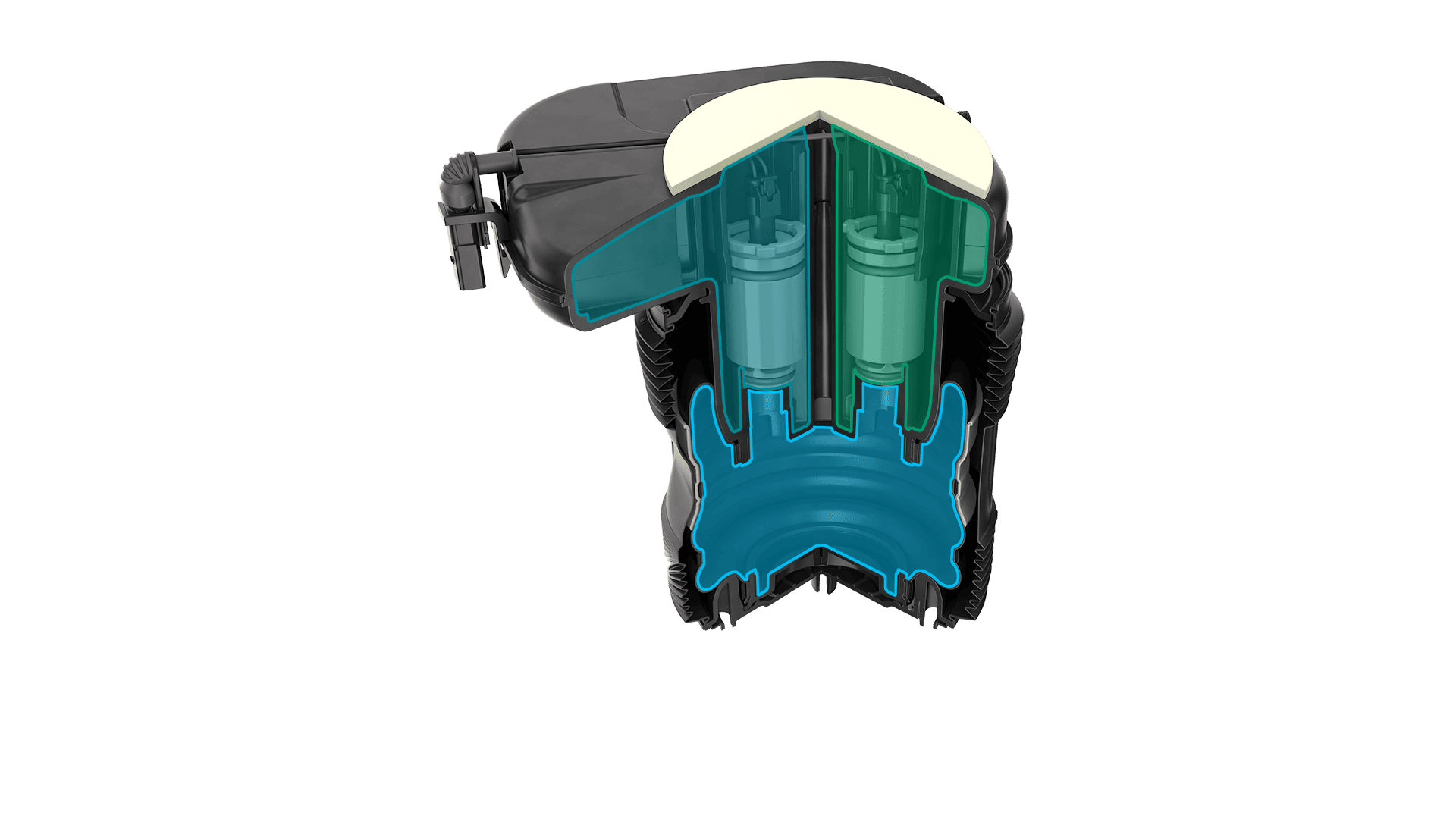

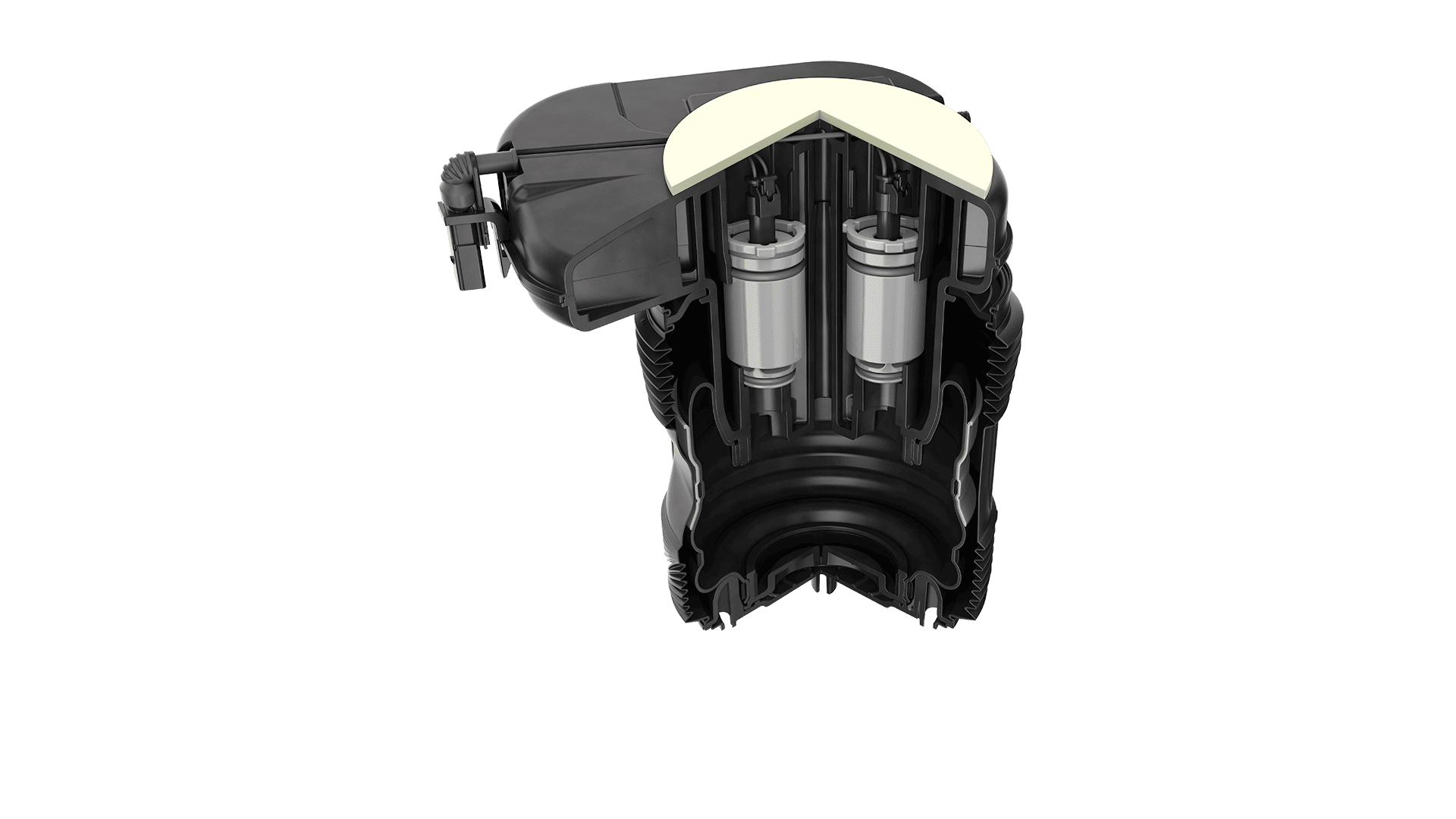

Concept of the three-chamber air spring system: The larger the available air volume, the softer the springs; the smaller the air volume, the stiffer the springs. Vibracoustic switchable air springs allow the stiffness of springs to be doubled over four gradients – from very soft to extremely stiff.

To enable this, Vibracoustic switch valves control the air flow rates and their openings need to be adequately sized for the correct amount of air to pass. The switching times also need to be short enough to enable stiffness switches to be made at speed. To ensure that switching noises are not perceptible by passengers, an optimized membrane is used. This feature is particularly important for electric vehicles, where there is no combustion noise or vibration from the motor to mask this type of noise.

To build the new geometries of the air spring, including the straightforward creation of air volume chambers, Vibracoustic uses an innovative hot gas welding manufacturing process for the air spring top pot. This allows more efficient use of the limited packaging space in the suspension area by combining various plastic and aluminum parts. The result is a weight reduction of the top pot by up to 30%.

Switchable dual-chamber air spring systems are also possible. They only offer two different stiffness levels, but still enable effective roll stabilization and are therefore a cost-efficient system to meet customer demands for improved comfort and driving dynamics in high- and medium-segment vehicles.