Air Springs with Axial Sleeves

Provide optimal comfort at very low friction levels

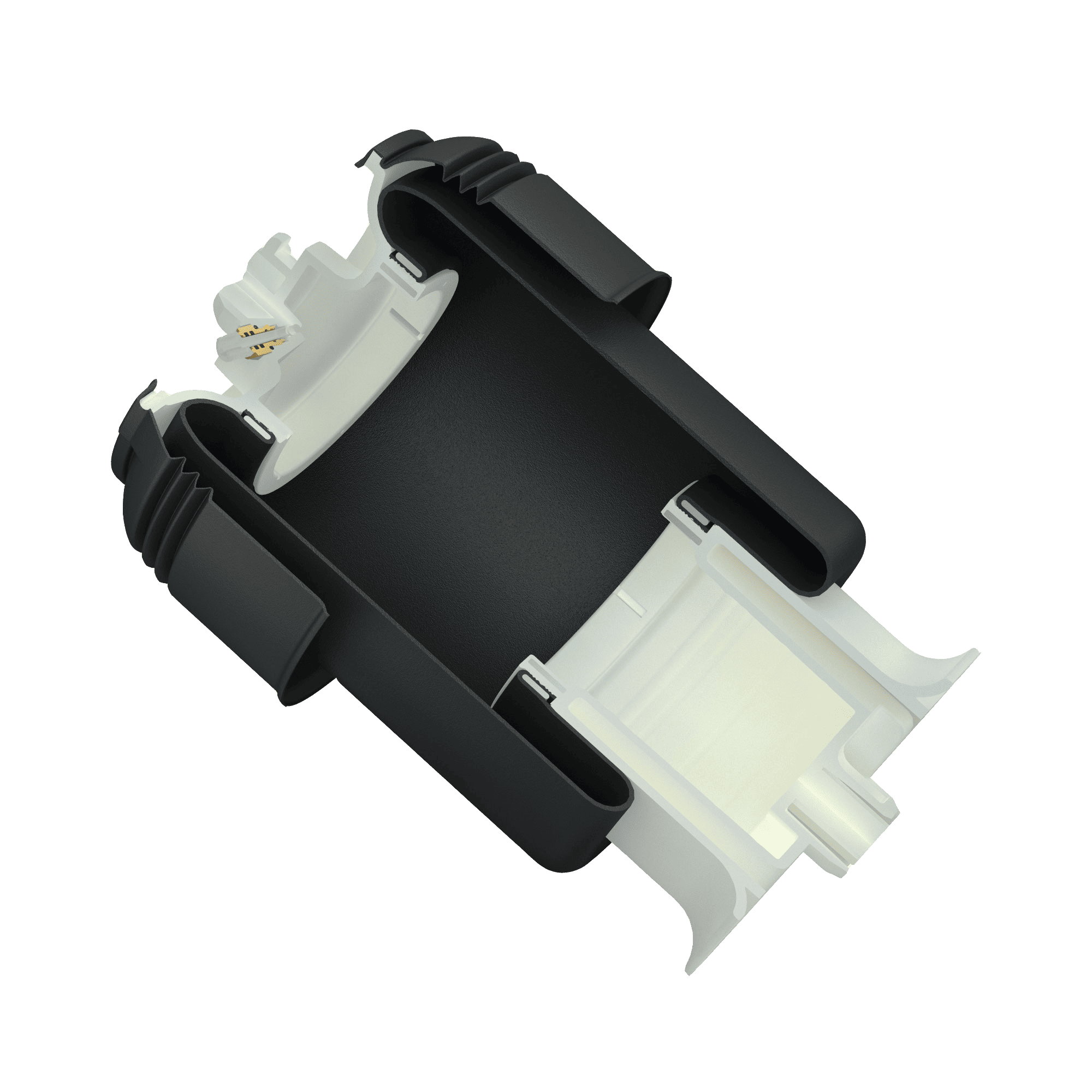

Lightweight hybrid air pot with innovative hot gas welding technology

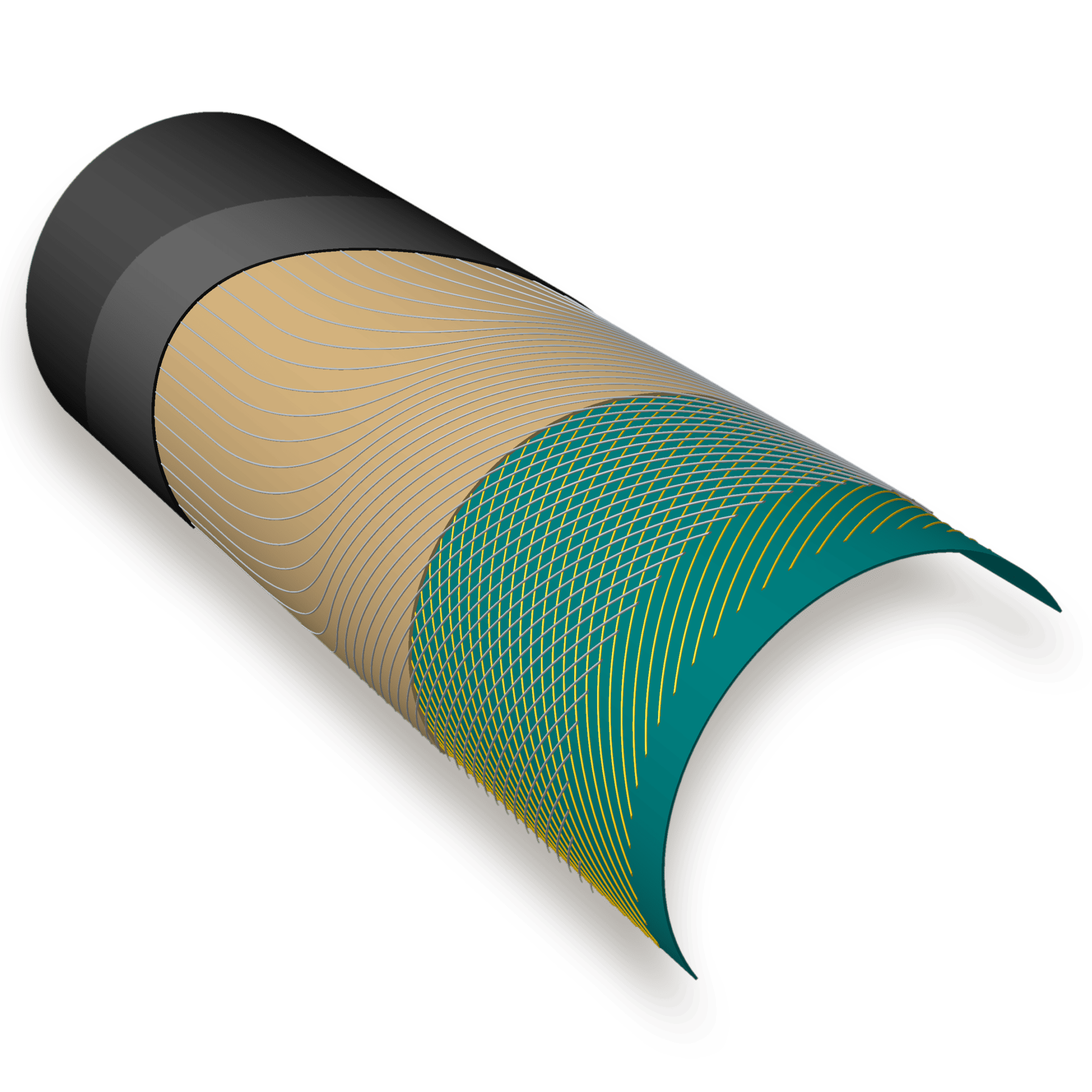

Ultra thin axial fiber-reinforced rubber sleeve

One-piece contoured aluminum piston for maximum air volume and comfort

Non-pressurized (sealed) top mount for optimal harshness performance

Air springs with axial sleeve technology provide optimal comfort and are mainly used at the front axle. The extremely thin air spring sleeves, combined with axially extending fiber reinforcement, result in very low friction levels.

The axial sleeves can be used flexibly and combined with various air spring technologies. Non-pressurized top mounts can provide optimal harshness performance, whereas one-piece contoured aluminum pistons provide maximum air volume and comfort. Lightweight hybrid air pots, made of die-cast aluminum and polyamide using innovative hot gas welding technology, guarantee excellent performance.

Vibracoustic was the first supplier of this special axial sleeve technology, since when axial sleeves from Vibracoustic can be found in almost all front axle air springs for light vehicle applications.