Darmstadt, 15. March 2019 |

Vibracoustic technology for a comfortable SUV driving experience

Today every fourth newly registered car is either an off-road vehicle or SUV. In terms of buyer’s favor, the SUV segment has in effect overtaken even the hitherto most successful segment of compact cars. Consequently, car manufacturers are constantly presenting new SUV models in all sizes, also at this year’s Geneva International Motor Show. This is despite the fact that very few buyers actually plan to take their vehicle off road. What does attract buyers to SUVs is rather the elevated seating position, and the better overview it gives them in city traffic. This is why car designers are refining the new models to make them suitable for everyday use and enhance driving comfort. A key factor in this effort is the deep expertise of Vibracoustic, a leading supplier of vibration control solutions. Today the products made by the German-based company already ensure driving comfort and safety in every second SUV manufactured in Europe and thus turn rough workhorses into elegant and smooth vehicles for everyday use.

When a customer goes for a test drive, the first three minutes are the most crucial. How much vibration is there when starting the car, how smooth is the ride over the first bumps, and how quiet is it inside while driving? Especially in the case of SUVs with their greater weight and all-wheel drive, this presents the designers with a special challenge, because potential buyers will compare them with vehicles of a lighter build, like sedans, station wagons and compact cars. The key to overcoming this particular challenge lies in the vibration damping solutions hidden deep inside the vehicle, out of sight for most drivers. “We add comfort to mobility. Almost all top light vehicle manufacturers around the world rely on our expertise in producing solutions that increase driving comfort,” says Frank Müller, the CEO of Vibracoustic AG in Germany. And the figures certainly speak for themselves: Every second SUV built in Europe today comes equipped with Vibracoustic products, and 19 of the top 20 light vehicle manufacturers work together with this supplier.

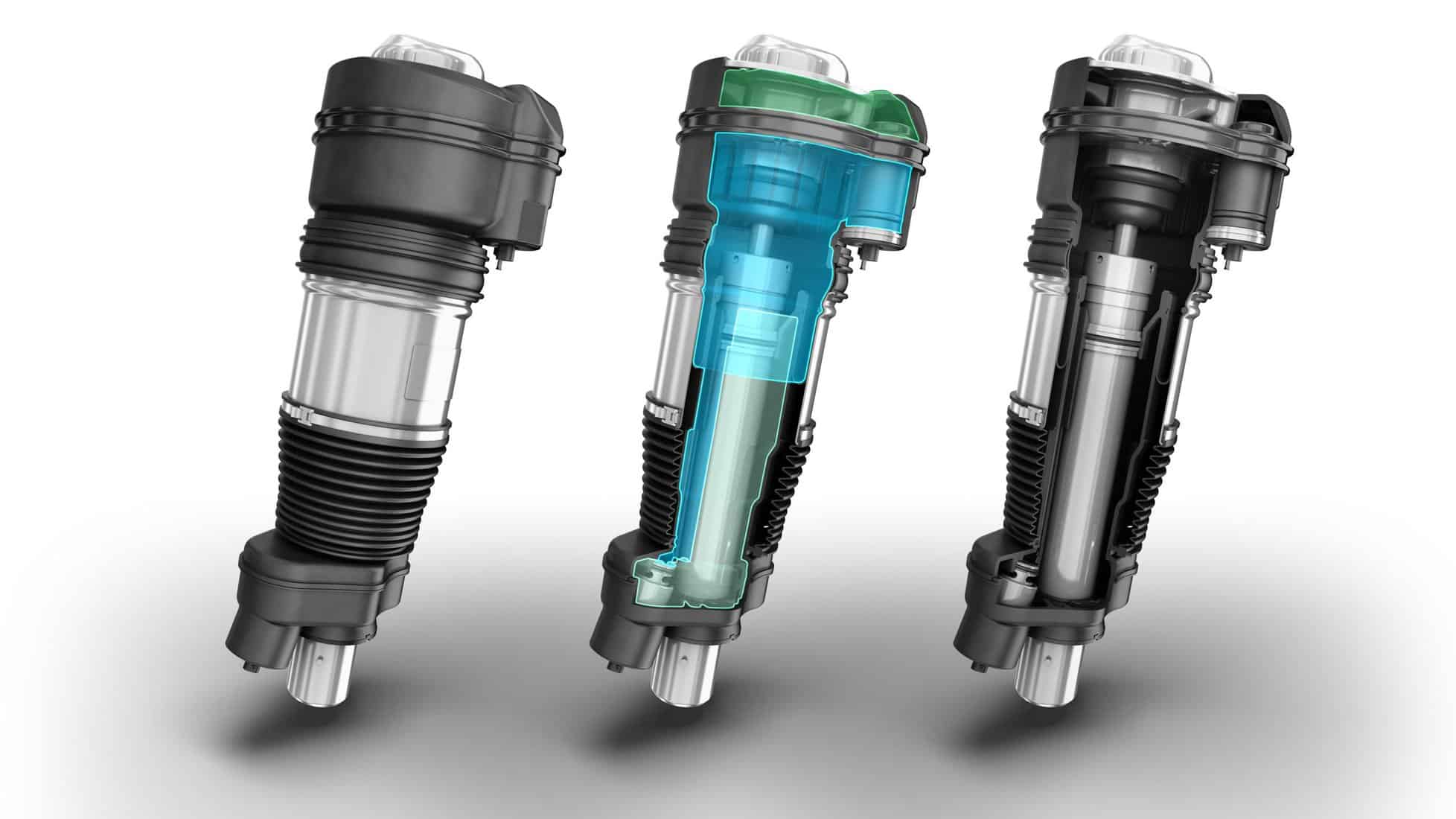

The company’s entire focus is on keeping noise, vibrations and external influences away from the passengers of the car with the help of NVH (Noise, Vibration and Harshness) solutions. To achieve this goal, the company for example develops suitable components for engine mounts and chassis, applying creative design principles, new combinations of materials and innovative manufacturing processes. The latest innovation is a three-chamber air spring system. By selectively activating or deactivating individual air chambers, the air springs adjust to different levels of stiffness depending on the driving situation to ensure a comfortable, quiet and safer ride. The current model of the Porsche Cayenne is the first production vehicle featuring this three-chamber air spring system.

With such innovations, Vibracoustic has become a leading player in the automotive industry. “The OEMs rely on our innovative strength and global manufacturing network to help them increase driving comfort in every vehicle class, and with every type of drive concept,” says Müller.