Darmstadt, 29. October 2020 |

Vibracoustic hydro motor mount with passive switching function offers excellent driving comfort and reduced component complexity

Downsizing combustion engines is a successful way for car manufacturers to tackle the increasing emission restrictions. However, smaller engines with fewer cylinders lead to increased engine noise and vibrations. Vibracoustic developed a hydro motor mount with a passive switching function for three- and four-cylinder combustion engines to address this conflict. This solution adapts its damping performance based on the excitations coming from the engine and so secures the driving comfort of the vehicle without the need of external electric or hydraulic switches. This significantly reduces the component complexity while offering excellent driving comfort.

The passive switchable hydro mount is a suitable solution for three- and four-cylinder engines where increased vibrations are a challenge due to the higher torques, combustion pressures, fewer cylinders of the engine or even an omitted balancing shaft. The hydro motor mount with a passive switching function is a smart and cost-efficient solution to reduce the idle dynamic stiffness by up to 45 % compared to standard decoupling solutions. This leads to an improved transfer function or in other words – less transmitted vibration.

Damping and stiffness are two key characteristics for the motor mounts since they have to both absorb vibrations coming from the engine while at the same time carry its static and dynamic weight. The advantage of the passive switchable hydro motor mount is that the switch between high road shake damping and low idle stiffness happens passively, i.e. without any external electronic or hydraulic trigger. This positively impacts the weight and design space needed and reduces complexity when compared to other switchable motor mount solutions. Thus, it represents an appealing solution for light vehicle manufacturers, who want to provide optimized driving comfort also in lower car segments while searching for a price competitive solution to conventional switchable hydro mounts.

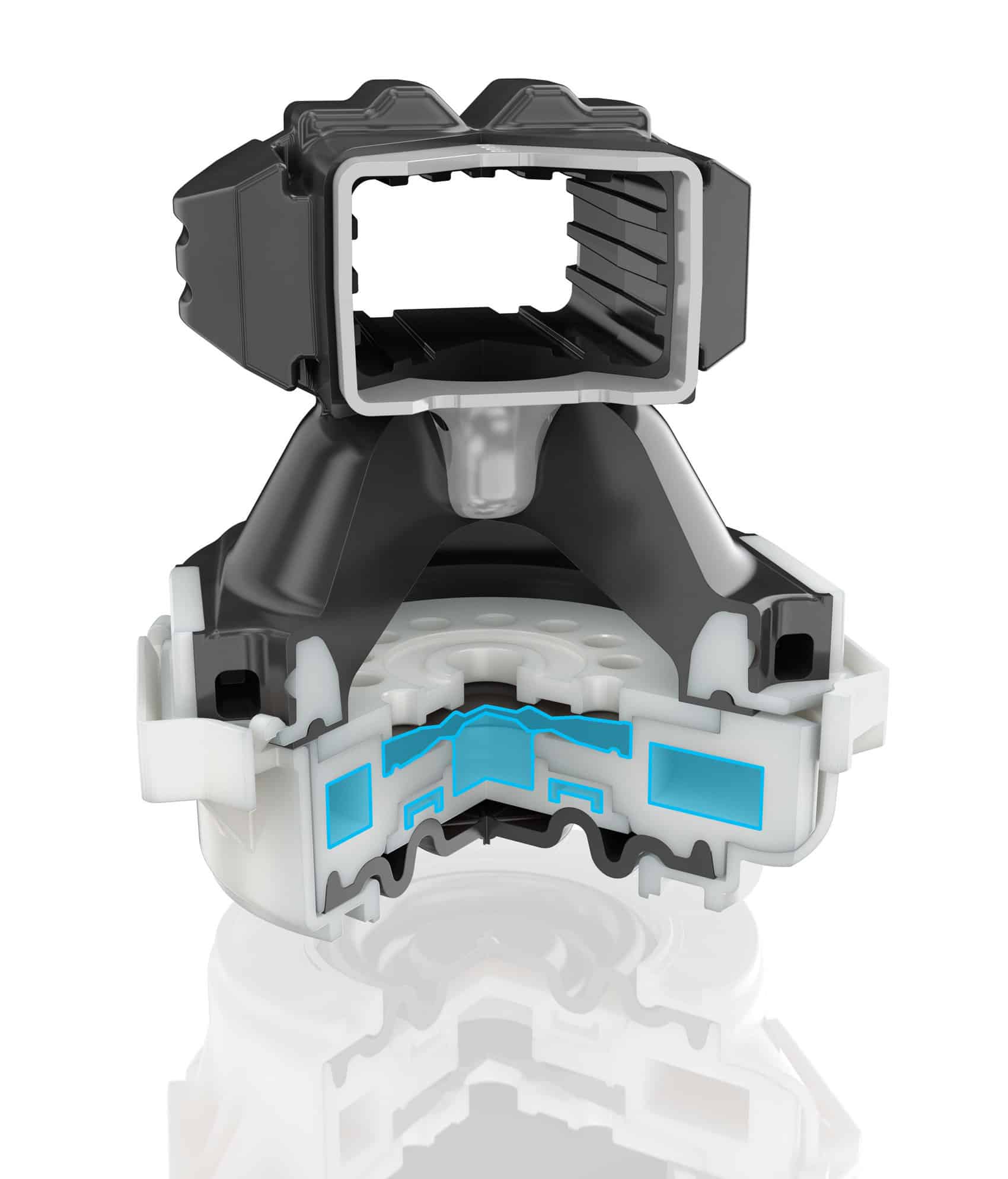

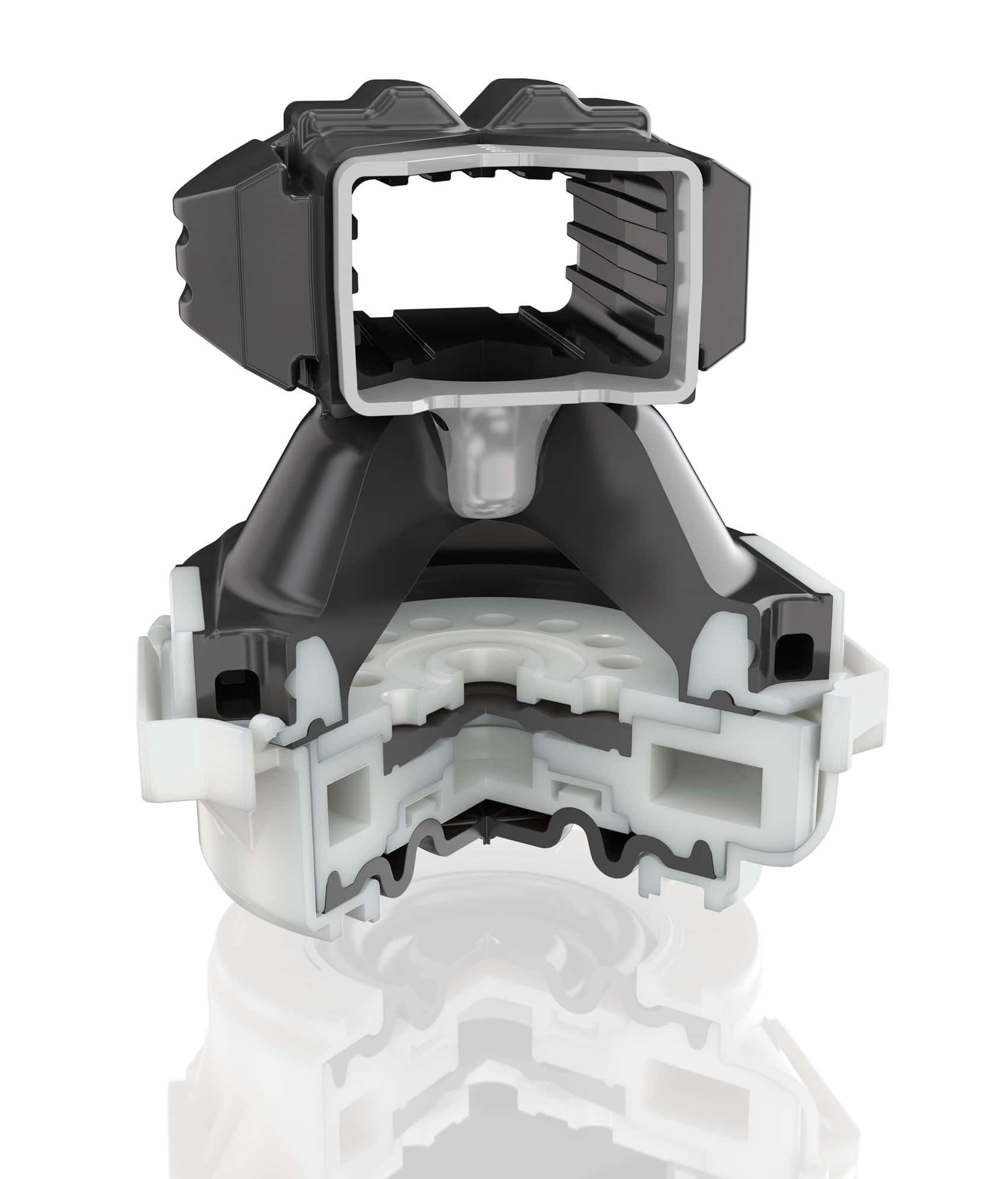

Passive switching function of the hydro motor mount

The hydro mount with passive switching function accomplishes stiffness reduction in idle mode through the integration of an additional channel. A membrane opens or closes the connection to the second channel depending on the amplitude of the excitations coming from the engine. When the excitation amplitude exceeds a certain level, the membrane closes, which increases the pressure on the fluid and provides a high damping level of the part, thereby securing good driving comfort – shake performance – for the vehicle. Now the mount operates like a conventional non-switchable hydro mount.

When the amplitude of the excitation is below a certain level, for example when the engine is in idle mode, the membrane opens and lets the glycol flow through the second channel. The moving fluid is acting as a damper and generates a stiffness dip below the resonance frequency. That allows the part to adapt the damping performance and decreases the unwanted vibrations transferred to the car body. This frequency of the stiffness dip can be tuned to the needs of the engine, making this solution applicable to both petrol and diesel engines as well as to hybrid powertrains.